Introduction

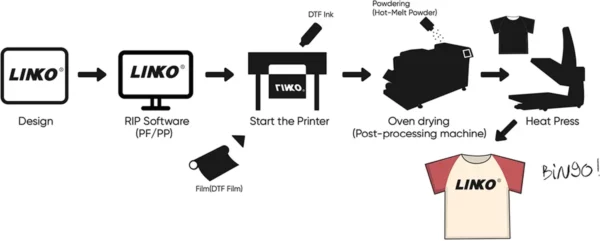

Unlike other methods, DTF printing involves several stages before achieving your hoped-for transfer. If you ever tried doing it or are an expert in this process, you can vouch that it is more complex. This means that even one misstep can derail your whole printing process.

Among the likely issues you can encounter is the DTF transfer not sticking. If this is your concern, you’ve come to the right place.

This easy guide will help you find out why your DTF transfer isn’t sticking to your canvas and how to fix it.

Reasons for DTF Transfer Not Sticking

Since DTF transfers involve several steps, you’re vulnerable to making mistakes that can cause the transfer to fall off. But, have you ever pinpointed where or what you did wrong to deal with this printing mishap?

Here are the potential culprits to why your substrate wouldn’t welcome your design:

Heat press: Insufficient heat or pressure

Heat pressing carries a critical role in ensuring your DTF design adheres to the fabric. It’s a step that needs calculated temperature and pressure to ensure the design is glued well.

Activating the DTF inks without the proper thermal configuration and pressure is difficult. Setting the temperature lower cannot melt the ink enough for ideal adhesion. Remember that improper melting is equal to poor adhesion.

Also, low-pressure applications yield similar problems. Adequate pressure ensures that inks seep and embed well into the cloth fibers. You can only expect the ink to achieve a shallow surface adhesion when you’re not pushing hard enough.

Environmental factors

Another key to unlocking successful DTF transfers is ideal and consistent environmental conditions. For example, poor ventilation leads to improper powder curing and prolonged canvas drying.

Humidity also causes problems as it can degrade your supplies. If you let moisture touch your powder storage, you’ll deal with clumpy adhesives. Ultimately, if you insist on using such a damaged product, you’ll get inconsistent design adhesion.

Dust and debris can also land on your substrate, leaving you with irregular transfer.

Insufficient or excessive powder

You wouldn’t want to take on the first few steps of DTF printing only to achieve inconsistent design adhesion. This is often the product of applying a scant amount of adhesive powder that fails to cover the whole film. Design surfaces that do not get enough powder will not stick to the shirt and peel sooner.

Adding too much powder also wastes your initial progress. Thicker adhesive means heavier and raised texture. This runs in contrast to the desired flat and leveled transfer that is less likely to crack and peel.

Transfer film quality

Substandard transfer films are known to have inconsistent coatings and poor adhesive layers. If you insist on using these films, your design will partially or entirely fall off.

Low-quality films often also have inconsistent release layers. This can make peeling difficult and harm the transfer adhesion.

But substandard films aren’t the only ones that can trouble you. High-quality films that are mishandled or defective can also cause similar issues. Torn or scratched films lose their effectiveness even if they come from reliable brands.

Premature peeling

Early peeling of the film post-transfer will yield an adhesion setback. When you peel it shorter than its prescribed cooling time, you’ll likely end up with incomplete adhesion or, worse, a distorted design.

It also helps to familiarize yourself with whether you’re using a hot or cold peel technique. A hot peel needs a shorter cooling time than a cold peel. Sometimes, when you peel too soon, the ink can be lifted, triggering the transfer not to stick.

How to Fix the Problem of DTF Transfer Not Sticking?

Resolve your DTF adhesion problems with these tested measures:

Regularly Testing and Replacing Low-Quality DTF Powder or Ink

Cheaper consumables don’t guarantee savings. You’ll learn this the hard way if you settle for low-quality products.

Testing DTF powders and inks will show you their adhesion and vibrancy. Having first-hand test results should give you an idea of how one brand compares to others. These results should lead you to the product with the best overall quality.

It’s also vital to only source products from reliable suppliers to avoid second-rate supplies. And make sure you’re not getting consumables past their expiration or are defective.

Choosing the Right Substrate for the DTF Transfer

Choosing a suitable substrate means matching it with your DTF powder and ink. While DTF printing favors many fabrics, some adhesives and ink are incompatible with any surface.

If you’re sticking to one brand or type of these supplies, ensure your fabric of choice welcomes them. As you may have noticed, some fabrics work better with specific inks and refuse others.

You can experiment with different fabrics and consider their textures. Choose those that work well with your chosen powder and ink for the best results.

Optimizing the Printing Process

Optimizing DTF printing means your equipment and process are fine-tuned.

Start by calibrating your printer to its correct parameters. Keep an eye on the proper ink density and image resolution to fend off any printing errors.

Next is to set your heat press machine’s ideal temperature and pressure. But remember that there’s no absolute temperature and psi for all fabrics.

The proper configuration for polyester wouldn’t yield similar qualities if applied to cotton.

So, your best bet is to check the machine manual for guided calibration based on the fabric you’re working on.

Another thing is to observe proper curing time and film peeling. Both processes require proper timing to be effective. An adhesive powder that’s half-cured will not provide enough adhesion. Also, you must peel your film after cooling it down as prescribed.

FAQs

1. What temperature should I use for DTF transfers?

Temperatures for DTF printing vary based on the fabric. However, the typical range is between 300 and 350 degrees Fahrenheit (approximately 150 and 177 degrees Celsius).

You must press between 15-20 seconds.

2. How much pressure should I apply during the heat press?

The pressure appropriate for the DTF printing process also depends on the fabric. To determine the proper pressure, you must refer to the heat press machine manual.

Here’s a reference for pressure rating:

Light pressure: 25-30 psi

Medium pressure: 32-38 psi

Firm pressure: equal to or greater than 40 psi

3. Can I use a regular printer for DTF transfers?

No. Using a regular printer can compromise your transfer. It is advisable to stick to a printer with a compatible resolution, ink, and printing action.

If you’re cutting on DTF printer cost, you can opt for a converted DTF printer.

4. Why does my DTF transfer film peel off after washing?

Your DTF transfer is not supposed to fade or peel when washed. DTF is among those methods with a peel-proof guarantee, even through repeated washes.

Here’s a rundown of why your DTF shirt is peeling:

- You fail to cure the adhesive powder properly

- You did not apply the right temperature and pressure

- Materials used are of poor quality or expired

- Your fabric isn’t suitable for DTF transfer

- Insufficient or excessive powder application

- Premature peeling of the film

5. How can I prevent my DTF transfer from cracking?

DTF transfers are tested to be durable and long-lasting. Its premature cracking can result from using low-quality materials or inappropriate equipment settings.

Here are the conditions you can follow to steer clear of such trouble:

- Stick to the prescribed temperature setting based on the fabric

- Observe the proper amount and curing of the adhesive powder

- Apply the correct pressure during the design transfer

- Never settle for low-quality supplies and materials

- Do not use expired supplies

- Choose the right fabric

- Ensure correct peeling of the film post-transfer

- Pre-press your fabric to draw the moisture out and smoothen the printing surface

6. Can I reuse DTF transfer films if the transfer didn’t stick?

No. The rule of thumb says you can only use a DTF transfer film once. After running it on the printer or the heat press machine, you can no longer print on it again.

Printing and heat pressing the film removes its capacity to work as it should. The ink will only run off if you insist on printing on it twice.

7. What types of fabrics are best for DTF transfers?

DTF printing is the go-to technique for those looking for unmatched versatility. Whether cotton, pure polyester, or blended fabrics, DTF works without problems.

Additionally, you can use DTF on jet-black, white, or any other colored fabric. DTF is for all fabric types and colors.

8. Can environmental factors affect DTF transfers?

Yes. Conditions like extreme temperature, moisture, and dirt can compromise your DTF transfer. You must work in ideal conditions and store your materials in the proper environment. This way, you can be confident that nothing’s ruining your printing process.

9. How much does a DTF printer cost?

As you may know, the cost of a DTF printer can vary depending on its brand, features, and size. Converted DTF printers can cost around USD 500 to USD 1000.

Converted printers are a friendly choice for entry-level DTF printing ventures or hobbyists. But, you can still scale to more advanced and automatic models, although they can be heavy on your pocket.