Introduction

The global Direct-to-Film (DTF) printing market was estimated to be worth US$2.56 billion in 2023. This outstanding value is expected to grow at a 6.50% CAGR until 2030, putting it at US$3.99 billion. Such numbers speak volumes of how popular DTF printing is today and in the years to come. For that, many are racing to start their DTF printing businesses.

The growing trend of personalized and custom apparel influences this upward trajectory.

DTF printing remains a clear frontrunner for customizing versatile shirt designs. It is also a cost-effective method with a high-profit margin and minimal risks. No wonder it’s a sought-after business model for new and established clothing brands. So, to get a piece of this lucrative business, you need to check out this guide.

What is DTF Printing?

Whether new to printing, you’ve likely stumbled early with the direct-to-film method. DTF printing is well-known among hobbyists and established printing businesses.

DTF printing is a method that involves the use of PET transfer film and adhesive powder. As the name suggests, you’ll print your custom design on a transfer film before pressing it to the substrate.

Like other methods, it uses heat pressing to transfer the design to shirts. What’s most sought-after about DTF is its durable and vibrant finish. Once transferred to the substrate, the digital design turns crisp and sharp.

DTF printing offers versatile applications and cost-effectiveness as a business model. In fact, this technique has one of the highest profit margins compared to other methods.

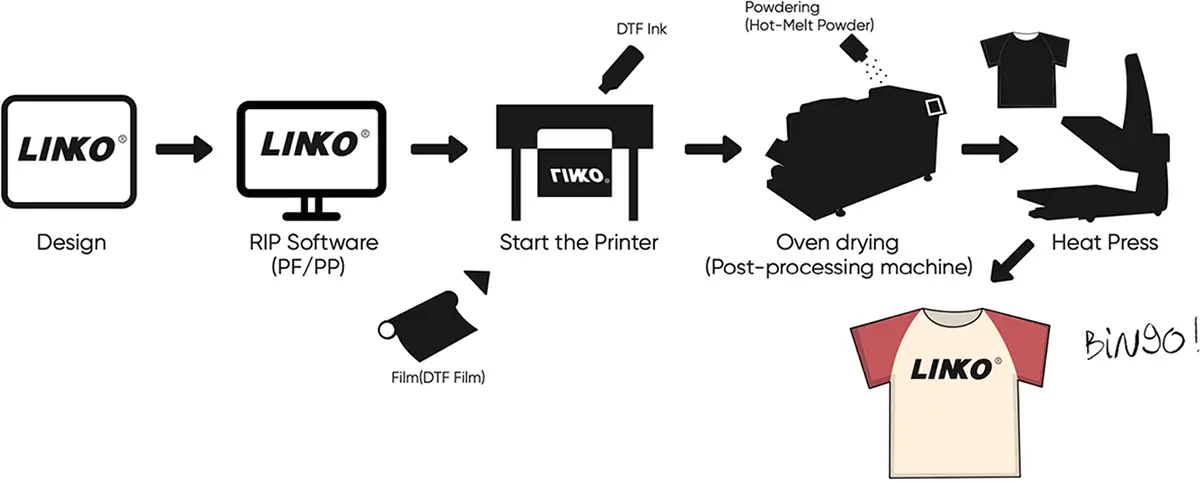

How to Print DTF Transfers?

DTF printing remains straightforward, although it features one or two more steps than other methods. Here are the steps included in DTF printing.

1. Creating Your Digital Design

DTF printing does not put strict limits on your designs. Since DTF works with white ink, you can create simple to complex designs that will still turn out vibrant after transfer. You’ll not be limited to printing on light-colored garments, as well.

You can use thousands of free images and vectors for your shirt design online. But you can use RIP software if you want a more custom template. Always save your file in a valid format for the DTF printer.

2. Printing On Transfer Film

The most notable step in this technique is printing on a transfer film. After all, including a transfer film distinguishes DTF printing from others.

You can print via a standard inkjet printer with six ink tanks to accommodate the white ink. You can also upgrade to an integrated DTF printer for better features. Nonetheless, ensure you’re always in stock and that your printer is loaded with transfer films. You can also choose between hot or cold-peeled PET transfer films.

3. Applying DTF Transfer Powder

Another notable step in DTF printing is the application of hot-melt adhesive powder. Some advanced DTF printers feature automatic powder shakers. But if you don’t have one, you can apply the powder by hand and shake off the excess later. You must cover all the inked areas of the film with the right volume and consistency for better results.

Powdering is done after fresh printing on the film. Once powdered, you must cure the adhesive to bond with the ink. If you lack a curing oven, you can also use the heat press machine to melt the adhesive.

4. Heat Pressing

DTF printing does not need pre-treatment of the garment. However, pre-heating the shirt for at least 5 seconds will help remove moisture.

The duration and temperature of heat pressing will vary based on garment type. However, the usual configuration is set at 170 degrees Celcius for at least 15 seconds. Removing the transfer film after the heat press depends on whether it’s cold or hot-peeled type. Hot-peeled films allow you to remove the film quickly after heat pressing. Cold-peel means you must rest the film until room temperature before removing it.

What Do I need to Print DTF Transfers?

DTF printing is cost-effective to set up. Once you secure the most essential equipment, you can move forward and scale your business. Here is everything you need to start DTF printing.

DTF Printer

If you’re a hobbyist or starting your printing business from the ground, a DTF printer could be your most significant investment.

You can start with a standard six-tank inkjet printer. These printers can work with DTF inks and will not compromise the print quality. Here is a comprehensive guide for beginners to choosing a DTF printer.

You can also look for used or modified printers in the market. You can scale up to automatic printers once you reach a specific printing volume.

Heat Press Machine

You can’t do DTF printing without a heat press machine. The good news is that you can look for one online and choose the best price. Modern heat press setups include rotating flatbeds for convenient and faster production.

This equipment also needs periodic maintenance checks, so invest in the most reliable brand. LINKO’s heat press machine is your first choice.

RIP Software

DTF printing is all about providing custom shirt designs. This means your business will more likely succeed if you have a brand. RIP software allows you to craft your digital template freely. It gives you control of what your brand can provide design-wise. It is still best that you equip yourself not just with the right equipment but also with design skills.

Powder Shaker

A powder shaker is a unique tool for applying adhesive powder to the transfer film. While you can do the adhesive application by hand, having this tool improves productivity. When your business handles more orders, a powder shaker becomes a necessity.

Curing Oven

A curing oven can be integrated into more advanced DTF printers. Some features include automatic curing after printing and powdering.

DTF Ink

DTF inks are pigment inks that are widely available in the market. This supply is easily consumed, so always have them in stock. You would also want to make sure your white ink is always available.

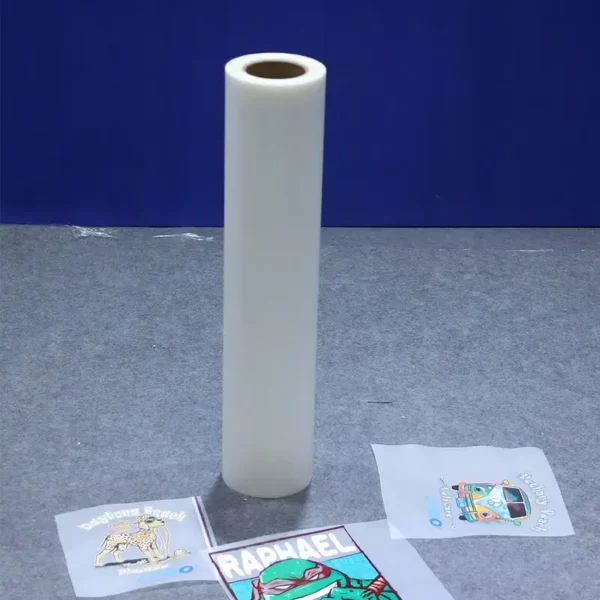

Transfer Film

Transfer films can be purchased in pre-cut sheets or rolls. You can also choose between hot and cold-peeled film types. Transfer films can be used only once and are easily consumed. Ensuring you have ample stock will guarantee smooth and continuous production.

DTF Powder

A DTF transfer powder is essential to help the ink bond more firmly to the fabric. It acts as a glue that allows the ink to stick to the substrate. You can only print DTF if you have this supply.

Pros and Cons of DTF

Like other methods, DTF printing also has its advantages and downsides. Here are its pros and cons.

Pros

- Offers durable and vibrant prints

- Cost-effective

- Fast production

- Versatile application

- Works with most types of fabric

Cons

- Non-breathable prints

- Plasticized transfer texture

FAQs

Q1: How much does DTF Equipment Cost?

The cost of DTF equipment depends on your preferred setup. These sets of equipment have a wide price range based on brand, features, and capacity.

You can have converted DTF printers if you want a more affordable option. They can cost you US$500 to US$1000. You can also expect to pay $200 to $500 for a decent heat press machine. But you still have the choice to go for bundled offers for more savings. The specific price will vary for different models, please contact us for a quote.

Q2: What is the difference between DTF and DTG printing?

Direct-to-film and Direct-to-Garment are two distinguishable methods. DTG directly prints on the garment by spraying water-based ink onto the substrate, eliminating the need for a transfer film. However, this doesn’t necessarily mean that DTG printing beats DTF in production time. In DTG, you’ll need to pre-treat the fabric, which slows down the process. This makes DTG more ideal for small orders. In terms of versatility, DTF remains on top. See more differences between DTF and DTG.

Q3: What is the difference between DTF printing and white toner?

DTF and white toner are two popular and versatile techniques. Both print on a transfer medium before transferring the design, and both need heat pressing for design transfer. The main difference is that white toner can print on soft and rigid substrates, while DTF is more exclusive to softer materials.

Q4: Is DTF printing right for you?

Deciding whether to use DTF printing over other methods should hinge on several factors. You need to understand what market you will be catering to. Or what products you are to offer.

DTF remains an outstanding choice for custom t-shirt design. It is also on top regarding the best options for garment printing, and for good reasons. So, when building a custom apparel brand, DTF is your best choice. It’s cost-effective, easy to operate, and has a better return on investment. Here is a guide to custom T-shirt printing at home using a DTF printer.

You can’t go wrong with DTF printing. As the best DTF printer manufacturer in China, LINKO will help you succeed rapidly in your DTF printing business.