LINKO KM-602 DTF Printer Product Parameters

| Attribute | Details |

| Model | KM-602 |

| Available Width | ≤620mm | ≤24.4 inches |

| Print Media | DTF Film, PP Paper |

| Print Head | Epson i1600A1 x 2 / Epson i3200A1 x 2 |

| Ink Color | CMYK+W |

| Temperature | 22°C – 28°C | 71.6°F – 82.4°F |

| Humidity | 45% – 60% |

| Capacity | 1200ml/color, Waste Ink Bottle: 3000ml/bottle |

| Print Speed (i1600A1) | 8Pass: 720 x 1200dpi, 4 – 6m²/h | 43.06 – 64.58ft²/h |

| 12Pass: 720 x 1800dpi, 2 – 3m²/h | 21.53 – 32.29ft²/h | |

| Print Speed (i3200A1) | 4Pass: 720 x 1200dpi, 8 – 13m²/h | 86.11 – 139.93ft²/h |

| 6Pass: 720 x 1800dpi, 6 – 10m²/h | 64.58 – 107.64ft²/h | |

| 8Pass: 720 x 2400dpi, 4 – 6m²/h | 43.06 – 64.58ft²/h | |

| Print Interface | RJ45 Cable Interface |

| RIP Software | PrintFactory, Photo Print |

| Operating System | Windows 10 / Windows 11 |

| Electrical Parameters | 220V/110V, 1200W |

| Machine Size | 1290mm x 612mm x 1453mm | 50.79″ x 24.1″ x 57.2″, N.W 105kg |

| Package Size | 1480mm x 700mm x 820mm | 58.27″ x 27.56″ x 32.28″, G.W 135kg |

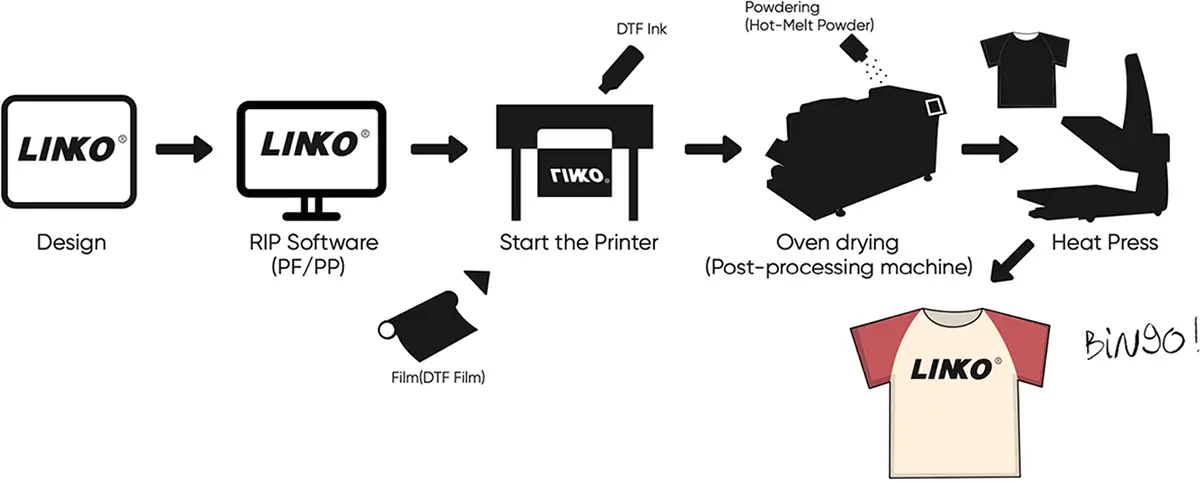

T-shirt Printing Process

Pattern Design

Design or adjust the pattern to be printed, and import the design file into the DTF printer.

Printing Process

After the pattern is printed, evenly apply hot melt powder to the pattern on the transfer film.

Drying Process

Put the transfer film coated with hot melt powder into the drying equipment for drying.

Transfer and Peeling

Use a heat press to perform heat transfer at the set temperature and time, and finally peel off the transfer film.

Related Consumables

DTF Printer Applications

This A1 DTF printer is suitable for personalized T-shirts, hoodies, hats, gloves, socks, canvas bags, shoes, uniforms, logos, matching clothing, team clothing, campaign clothing, etc. It is perfect for textile gifts and small batch production.