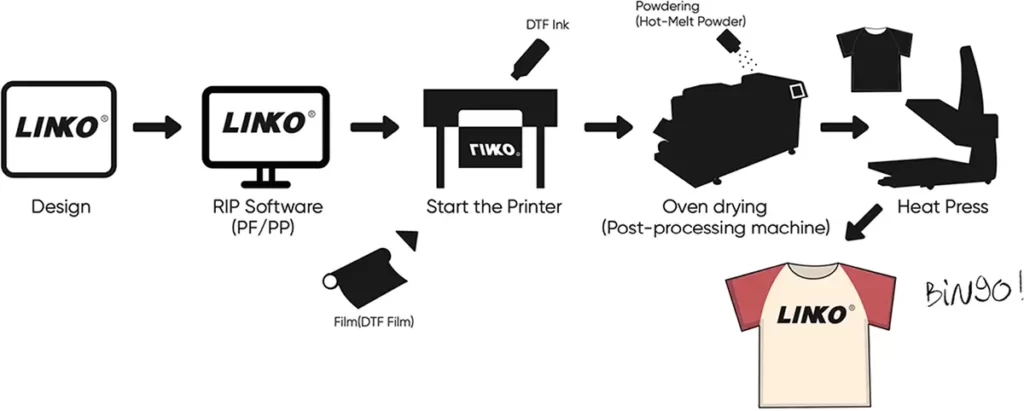

How Does the DTF Transfer Process Work?

How to Prepare DTF Transfer Paper for Printing?

Once you have the DTF Transfer Sheets, all you need is a heat press!

DTF Heat Pressing Instructions

- Set Temperature, Time and Pressure

Use 60 PSI Pressure for All Fabrics- Cotton: 325°F / 15 Seconds

- Polyester / Tri-Blends: 275°F / 10 Seconds

- 50/50: 300°F / 12 Seconds

- Pre-Press (5-7 seconds)

Pre-pressing removes any wrinkles from your fabric and also helps absorb any moisture from the garment. - Place your Transfer, then Press

Place your transfer sheet on the garment and lay a sheet of Teflon or parchment paper over the transfer. Then press at the desired temperature and time as shown in Step 1 (ensure you have pre-set your press to 60 lb of Pressure). - Peel

Peel after 10-20 seconds (when the film has cooled slightly), by peeling from one edge slowly to the other, in a rolling motion.

Hold down the garment with your free hand for better control. - OPTIONAL POST PRESS – For a Matte Finish

To achieve a matte finish, press for another 7-10 seconds with less (medium) pressure after peeling off the kraft paper (after step 4).

Benefits of Custom DTF Transfers

- Print Quality: DTF transfers are easy to use, detailed, colorful, and won’t fade.

- Versatility: Prints can be transferred to T-shirts, bags, hoodies, and more. It can be seamlessly stitched onto a variety of textile fabrics, including cotton, polyester, and blends.

- Low-volume customization: Great for small to medium-volume projects. It avoids the setup costs of screen printing.

- Eco-Friendly: DTF water-based inks are environmentally friendly. They are safer and more sustainable than some other printing methods.

DTF transfers are a perfect choice for a startup or small order. You can create high-quality, full-color designs on clothing or other textiles. They are suitable for small business owners, artists, and hobbyists.

How To Customize DTF Transfer Sheets?

You can contact us via email at [email protected] or WhatsApp at +86 133 9298 3556. The specific ordering process is as follows:

Step 1: Upload the pattern you want to print

We provide T-shirts in multiple colors. After uploading the pattern, you can freely adjust the pattern size, position and quantity, and provide a preview effect.

Step 2: Select the material properties for proofing

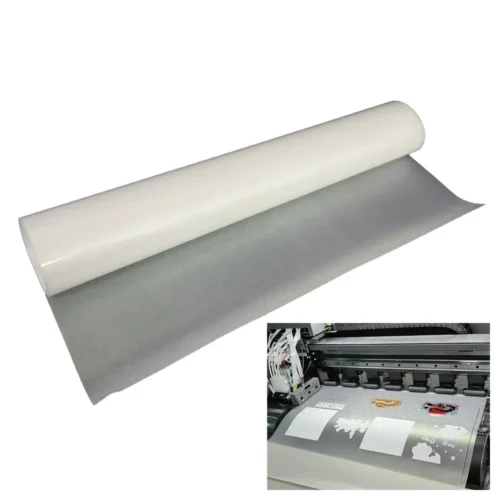

- Sheet (A4/A3), size can be marked

- Single sheet, easier to save and hot stamp

- Suitable for small batches and first-time customers

- Does not support patterns larger than A4 size

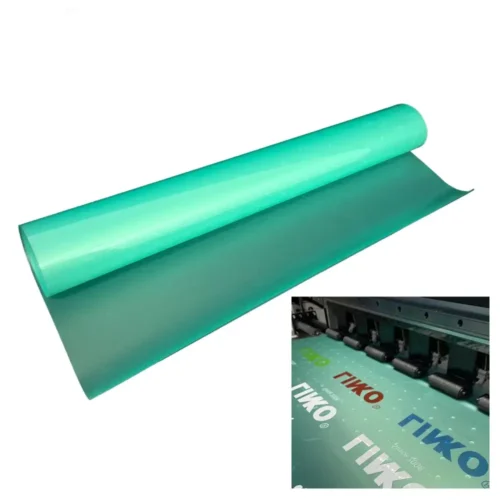

- Roll (no display of hot and cold tear single and double sides)

- Free layout, no limit on pattern size

- Suitable for customers who produce in large quantities

- More cost-effective than sheet

Step 3: Submit the pattern source file

Source file requirements:

- Due to the difference between RGB and CMYK color modes, pattern creation needs to adjust to CMYK for printing.

- We do not provide color matching services. If there are multiple color schemes, please upload them separately.

- We will print according to the CMYK value of the source file color mode. Due to temperature, humidity, ink batches, etc., these values may change slightly during printing. We cannot guarantee a complete color match, but please rest assured that the total color difference ΔE will not exceed 1.8.

- Supported file formats: PNG, PDF, TIF, PSD, AI, CDR

- Please send the file to the specified email: [email protected]

Step 4: Submit printing details

- Provide the size, quantity and color selection of the pattern (four or eight colors). We can layout according to your file.

Support uploading word, excel files, or arrange them in the order of source files. You need to choose the size, quantity and color of different files. - Provide your personal contact information (name, phone number, email and delivery address)

- Note any special requirements.

Note: Please contact us if you want to get an estimated price.

What are DTF Transfers?

Direct Film Transfer is a full-colour heat application transfer suitable for both light and dark garments.

No weeding or masking is required, allowing DTF transfers to be applied to cotton, cotton/poly blends, and even 100% polyester. (Please note that nylon is not recommended due to its smooth texture. The adhesive must bond with the fibers of the fabric.)

Frequently Asked Questions

Your order can be printed within 24 hours, and the logistics time depends on the distance of the destination country (we ship from Guangdong, China).

- Roll material: The minimum order quantity is 1 roll, the size is 30cm/45cm/60cm x 100 meters.

- Sheet material (A4, A3 size): The minimum order quantity is 5 packs, each pack has 100 sheets.

If there is a quality problem, we support return or replacement service.

Both matte and glossy effects are supported, just make a note in advance.

It is more suitable for printing on pure cotton fabrics or fabrics with a cotton content of more than 70-80%.

It is recommended to wash with warm or cold water to avoid deformation or fading of the pattern caused by high temperature. You can choose to wash by hand or use the gentle mode of the washing machine to avoid rubbing the printed area. Turn the garment over and wash it with the print facing inwards to protect the pattern.

Yes. We provide expedited service.

评价

目前还没有评价