Product Parameters - LINKO A602 DTF Printer, 24'' / 60cm

The Linko A602 DTF printer package includes a complete Direct-to-Film printing setup, consisting of a DTF printer, powder shaker equipment, oven, filter, 2 Epson print heads, DTF ink, DTF film, DTF powder, RIP software, installation videos, and one-on-one machine training tutorials.

| A-602 Series Direct to Film Printer | ||

|---|---|---|

| Brand | LINKO | |

| Model | A-602 | A-6028 |

| Available Width | ≤600mm / 24 inches | ≤600mm / 24 inches |

| Print Head | i3200A1*2 | i3200(8)-A1HD*1 + i3200A1*1 |

| Color | CMYK+W | CMYK+W CMYK+LCLMLKLLK+W |

| Print Speed | 4Pass: 10-15m²/h | 8Pass: 5-7m²/h |

| 6Pass: 5-10m²/h | 12Pass: 3-5m²/h | |

| 8Pass: 4-7m²/h | ||

| Printing Accuracy | 720*1200dpi, 720*1800dpi, 720*2400dpi | 720*1800dpi, 720*2400dpi |

| Print Media | DTF Film | |

| Application Scope | Nylon, chemical fibre, cotton, leather, swimsuit, diving suit, PVC, EVA, etc. | |

| Print Interface | Gigabit network port | |

| RIP Software | PrintFactory / Maintop | |

| Operating System | Windows 7/Windows 10 | |

| Electrical Parameters | 220V/110V, 1.5KW | |

| Size and Weight | Machine: 1336*658*1400mm, N.W 150kg | |

| Package: 1464*1000*711mm, G.W 180kg | ||

| Model | 24” powder shaker H-652 | |

| Available width | 0-60cm | |

| Voltage Power | 110/ 220V &3.5kw-5kw | |

| Machine size | 198.5*109* 108cm | |

| Weight | N.W 180kg G.W 260kg | |

| Support | Automatic shaking of hot melt powder | |

| Control way | Touch screen control panel | |

Linko A602 Product Highlights

Best Epson DTF Printer Bundle

High-Precision Printing Dual Heads

The ultimate DTF printer package with Epson i3200 dual head. Includes powder shaker for a seamless printing experience.

Up to 17- 24″ Wide Prints

Support your established business with versatile, on-demand short-run prints for various customized T-shirts.

One-Button Automatic Cleaning

Equipped with a one-button cleaning function, it ensures that the print head and ink system are always in the best condition.

LINKO A602 DTF Printing Machine Features

Comparison of 4-Color and 8-Color Printing Solutions

Professional Performance - Linko 24'' DTF Printer Core Technologies

Structural Design Of High-Precision Nozzle Bottom Plate

The new upgrade improves the design of the nozzle bottom plate. Our nozzle bottom plate’s processing accuracy can reach 0.01-0.02mm. After installing the nozzle, there is no need to adjust its angle and level. This can solve the problem of hard nozzle calibration. It will improve the material accuracy of nozzle installation.

Adopt One-Piece Aluminum Profile Mold/Industrial-Grade High-Precision Processing

The whole machine uses section aluminum and industrial-grade precision machining. This includes printing beams, bottom beams, front and rear arc plates, and printing platforms. These choices ensure the equipment runs stably and smoothly at high speed for a long time. They greatly improve print quality and extend the machine’s life.

The Automatic Control For The Electric Lifting Lever Of The Pressing Wheel

Improve the electric lift lever’s control method. Pressure rollers are at the front and back of the printer. The lift lever button is easier to use. This makes loading material faster and easier.

3-Way Integrated Touch Screen Control Board

The 3-way integrated touch screen controls front and rear heating, countertop lighting, and suction. It has a convenient and easy interface.

Integrated Servo Motor, Stepper Motor

The LeadShine integrated servo motor ensures the printing stability and the printing ink dots are more accurate. The paper feeding uses a stepper motor. It ensures the paper feeding is consistent and stable. It also improves the printing accuracy.

White Ink Automatic Circulation Function After Shutdown

An independent power supply and control circuit board have been added. When the machine is turned off, the white ink can circulate automatically. This prevents white ink from settling and clogging. It improves the nozzle’s lifespan and cuts maintenance costs.

Automatic Film Feeding Control Mode

The dual power feeding device and the tension rod are used. They ensure the film stays flat during printing.

The stable operation makes film feeding smoother. It improves paper feeding accuracy and printing quality.

Add a paper shortage alarm function. It ensures that printing stops when the paper is finished. The alarm can quickly prevent the material from continuing to print or other problems.

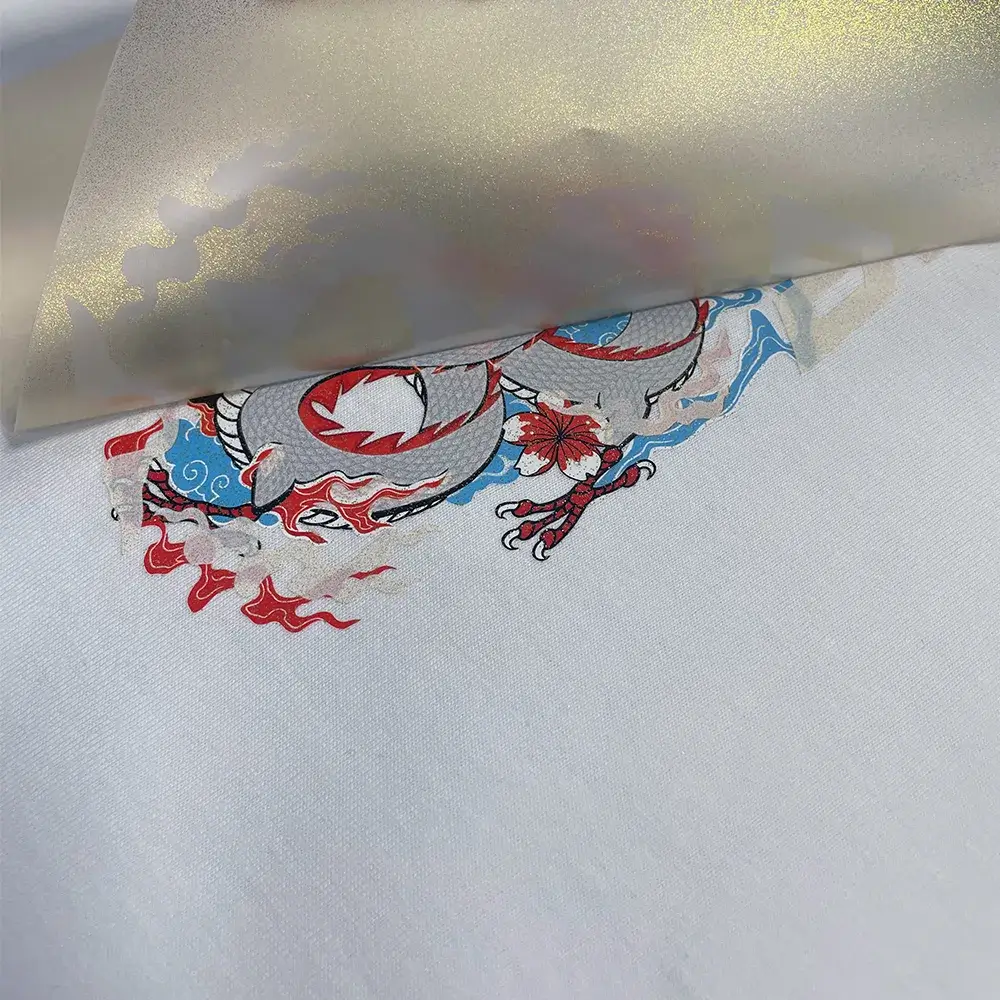

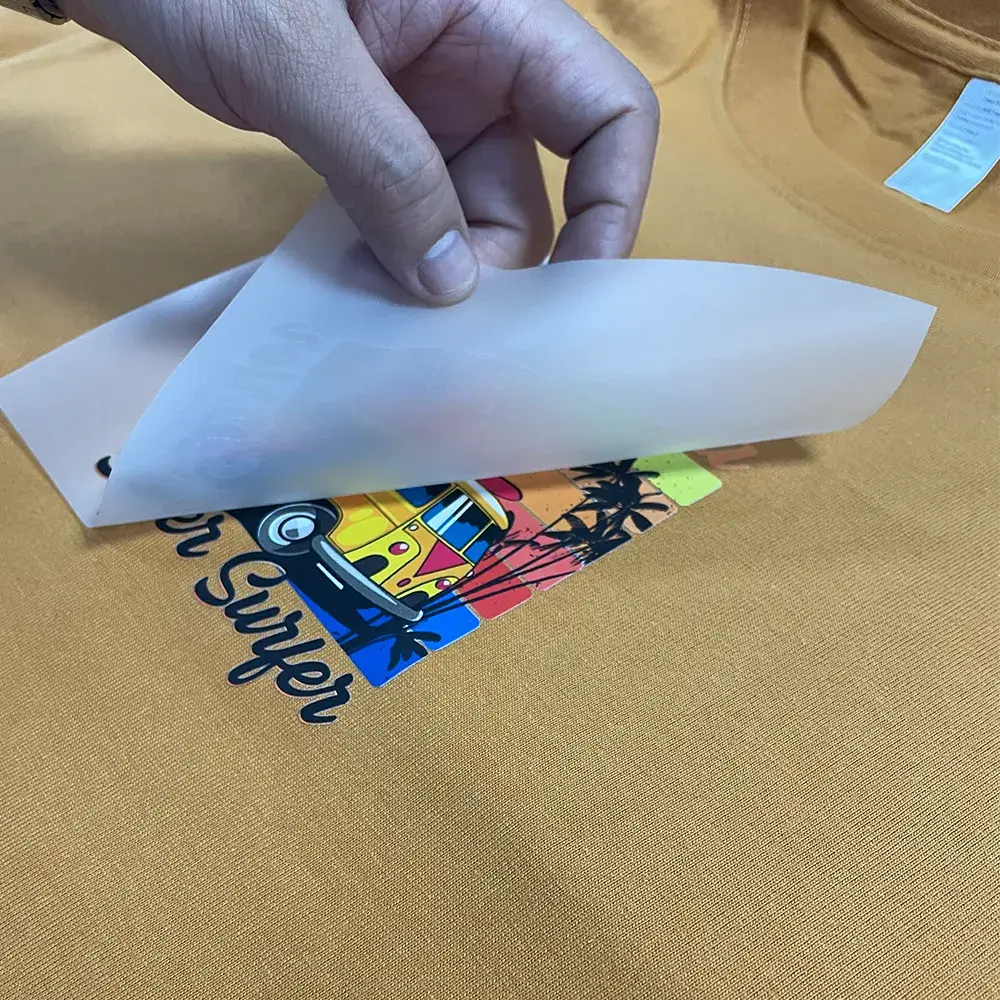

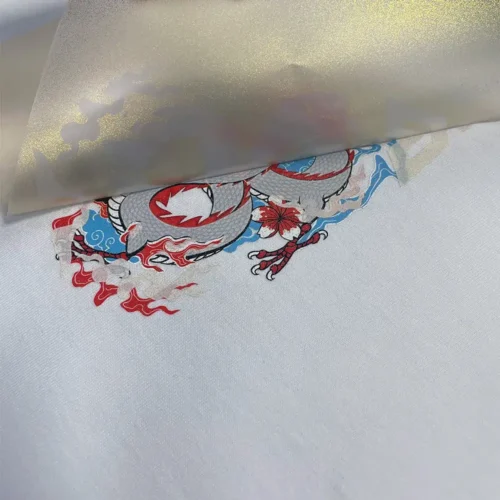

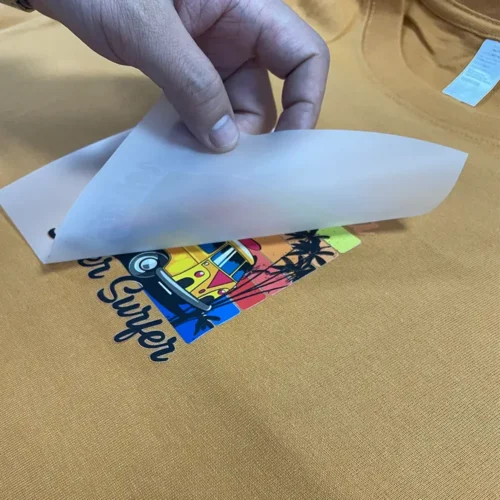

T-shirt Printing Process

1. Design The Pattern You like

2. Print Onto DTF Film

3. Shake Powder and Tumble Dry

4. Printed DTF Film

5. Hot Stamping

6. It’s Perfect

DTF Printing Consumables

DTF powder shaker

or

DTF oven

+

DTF powder+ink+film

+

Heat Press Machine

A1 DTF Printer Applications

The A602 series DTF printer is perfect for small business and medium-sized enterprises. It supports multi-color printing and works with fabrics of many colors and materials. Whether it is couples’ clothing, school bags, or fashionable canvas shoes, it can easily cope with it. The printing is excellent. It is also washable, stretch-resistant, comfortable, and soft.

Ideal for:

4A company, Advertising company, Printer service provider Fashion clothing brand owner Factory, T-shirts, goodie bags, Fashion design companies, Associations or organizations, Online influencer for product sales, Small-scale T-shirt production factory

评价

目前还没有评价