Product Parameters - LINKO A650 A1 DTF Printer

The Linko A650 DTF printer package includes a complete Direct-to-Film printing setup, consisting of a DTF printer, powder shaker equipment, oven, filter, 2 Epson print heads, DTF ink, DTF film, DTF powder, RIP software, installation videos, and one-on-one machine training tutorials.

| Model | High-Speed 24″ 60cm DTF Printer & Shake Powder In One A650 |

| Brand | LINKO |

| Print Head | Epson i3200 |

| Number of Heads | i3200 dual heads |

| Printing Width | <600mm |

| Printing Color | CMYK+W |

| Printing Media | PET film |

| Printing Speed | 6Pass, 10㎡/H |

| 8Pass, 8㎡/H | |

| Ink Type | DTF pigment ink |

| Printing Accuracy | 1440/2160/2880dpi |

| Print Media | Pet dd file |

| Suitable for Transfer Media | Nylon, chemical fiber, cotton, leather, swimsuit, diving suit, PVC, EVA etc |

| Rip Software | Standard PrintFactory(Maintop optional) |

| PC Operating System | Win7、Win10 |

| Platform Suction | Adjustable |

| Print Interface | Gigabit network port |

| Temperature and HumidityElectrical Parameters | 15- 30°C, 35-65% |

| Electrical Parameters | 220V , Rated current 30A ,Rated power6 5KW,Energy consumption: 3-6KW |

| Size and Weight | Machine:2130*1250*1216mm,N.W430kg |

| Package:Shaker1950*1350*1124mm,G.W 413 kg Printer1355*650*754mm,G.W 113 kg |

Linko A650 Product Highlights

High speed 60cm integrated DTF printing and powder shaking machine

Double i3200 Head High-speed Printing

Dual heads enable ultra-high-speed printing, improving production efficiency while ensuring high-quality print output.

Easy to Operate

Control touch screen, overall control software upgraded, more convenient operation. There is no need cut, No need to tear, No white edge

Anti-Collision System

During the printing process, it can detect and avoid collisions between the print head and the media or other components.

LINKO A650 DTF Printing Machine Features

Professional Performance - Linko A1 DTF Printer Core Technologies

Conveyor belt, dedicated powder control structure

The conveyor belt system has a dedicated powder control structure. It ensures precise powder application during printing.

Adjustable rotating touch screen

Provides user-friendly operation and customizable viewing angle for more convenient operation.

Low ink alarm, automatic ink lifting station

Remind the operator to maintain the optimal ink level to ensure continuous worry-free printing.

Extended dryer 2-stage drying channel

Dries printed products efficiently and thoroughly, ensuring high-quality output and faster production time.

Automatic paper collection system

Simplifies workflow and reduces manual operations by neatly organizing printed products.

High-speed printing technology

Equipped with ultra-wide format and multiple Epson high-precision print heads. It meets the personalized and mass production needs of large clothing manufacturers.

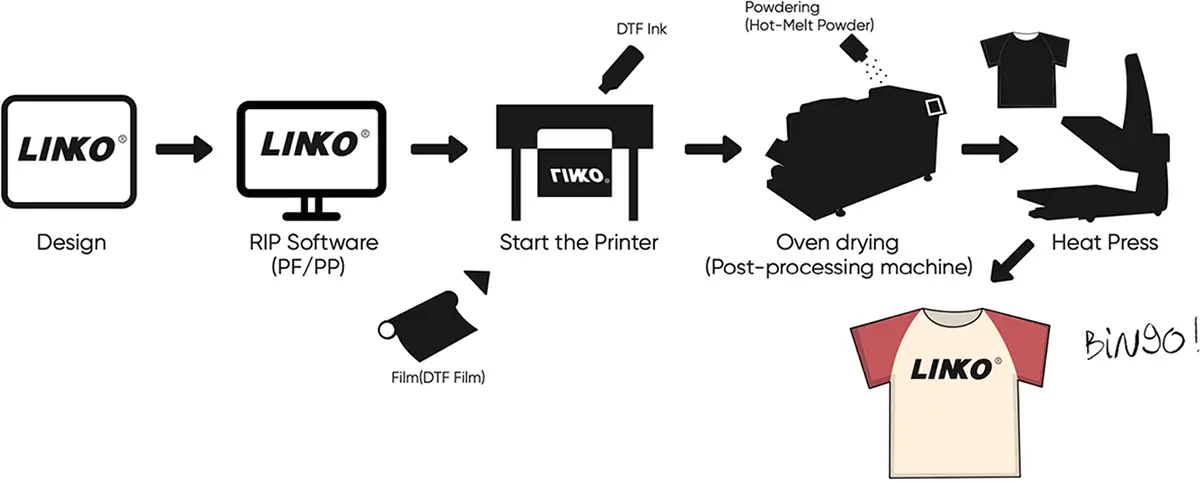

T-shirt Printing Process

Image Design

Edit and adjust the image using design software.

Film Printing

Use a DTF printer to print the image onto the transfer film.

Powder Curing

Sprinkle hot melt powder evenly on the printed film and cure it by heating.

Image Transfer

Place the film on the fabric and use a heat press to transfer.

A1 DTF Printer Applications

The A650 printer integrates a powder oscillator and dryer design, and supports fluorescent printing, which is very suitable for personalized clothing customization and professional mass production. It can be used in sportswear, T-shirts, hats, canvas shoes, etc.