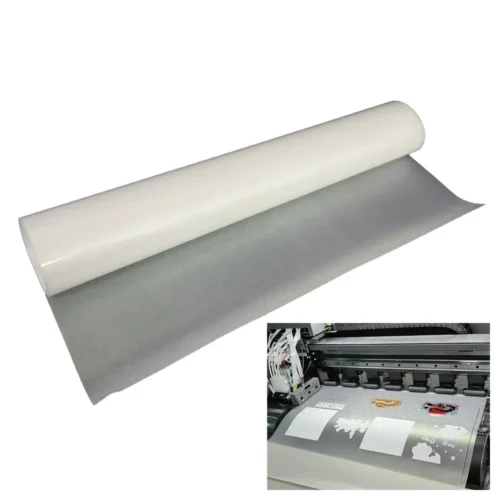

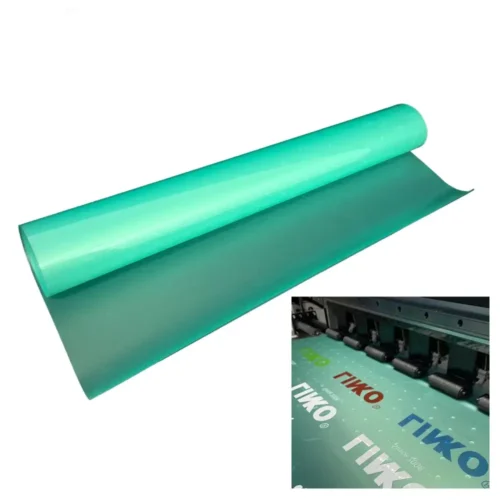

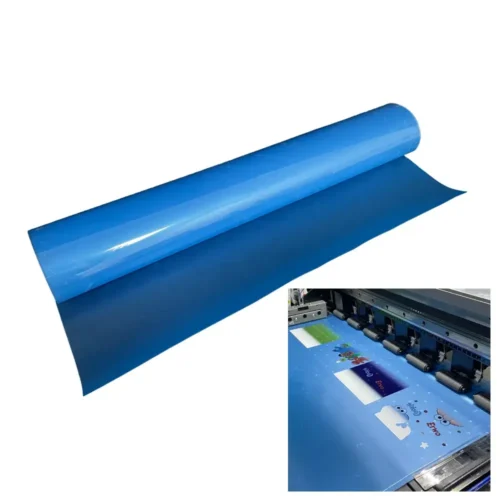

DTF Film: Unleash vibrant, lasting prints with our premium DTF Transfer Sheets and Films, assured quality for all DTF printer supplies.

| Essential details | |

| Industrial Use: | Business&Shopping |

| Use: | Promotion, Exhibition |

| Material: | PET |

| Type: | Twist Film |

| Usage: | Printing Film |

| Feature: | Water Soluble |

| Hardness: | Rigid |

| Processing Type: | Multiple Extrusion |

| Transparency: | Transparent |

| Place of Origin: | Guangdong, China |

| Brand Name: | LINKO |

| Model Number: | MA-134 |

| Product name: | PET Film for DTF Printer |

| Colour: | Clearing |

| Thickness: | 75μm-100μm |

| MOQ: | 1 |

| Payment: | 30%TT Advance |

| Diaphaneity: | Transparent |

| Core: | 3inch or 6inch |

| Sample: | Available(free Sample) |

| Application: | DTF PET Printing |

| Quality: | Excellent |

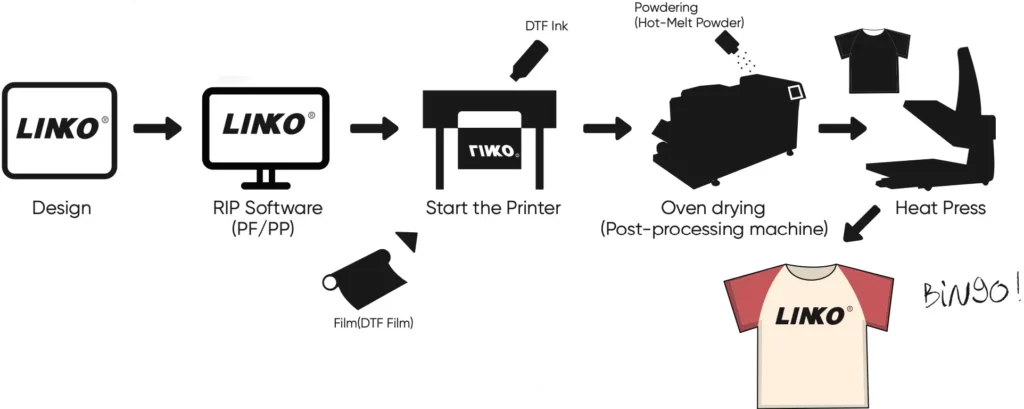

What is DTF Transfer Sheets?

DTF transfer sheets, also known as DTF film and DTF transfer paper, are mainly used for DTF printing.

The primary purpose of DTF transfer sheets is to be used for DTF printing. DTF printing is a heat transfer technology that uses DTF transfer sheets to transfer images to textiles.

DTF transfer sheets are made of PET film and heat transfer powder. The idea is printed on the PET film, and the heat transfer powder is used to adhere the image and transfer it to the textile.

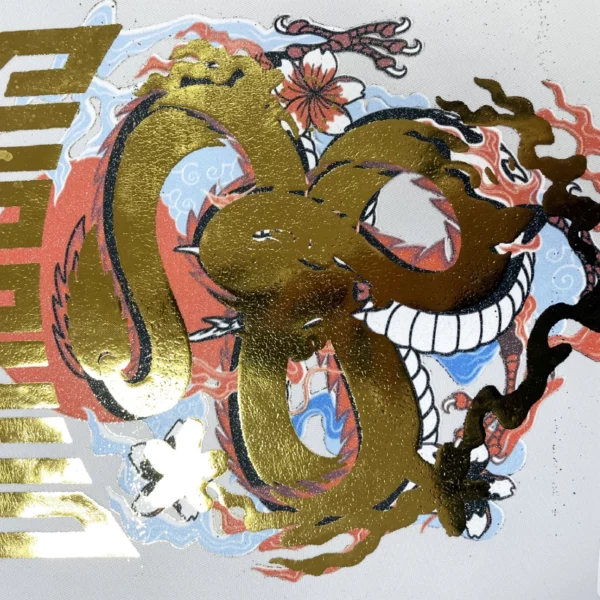

With a nod to their merits, DTF transfer sheets stand tall for a multitude of reasons:

- They gracefully embrace a diverse range of textiles, encompassing cotton, polyester, and even nylon.

- The images they conjure are not just vibrant but imbued with intricate detailing.

- Against the tests of time, they emerge triumphant as both washable and resistant to scratches.

In consequence, the canvas of possibilities for DTF transfer sheets expands wide. From imprinting T-shirts to emboldening sweatshirts, from adorning hats to bringing life to bags, DTF transfer sheets dance on the fabric of creativity, leaving their mark as an essential tool in the world of textile artistry.

How to Use DTF Transfer Film?

Preparation:

- Make sure the DTF printer is in normal working order.

- Have the required print design and image files ready.

Adjust Printer Settings:

- Load the DTF Film into the printer correctly and adjust the settings as needed.

- Ensure the printer’s printing parameters (such as temperature, speed, etc.) suit the selected DTF Film type.

Print Design:

- Use appropriate software to send the design or image file to a DTF printer.

- Make sure the size and position of the design or image file match the DTF Film.

Start Printing:

- Start the printer and start printing the design or image file onto DTF Film.

- Monitor the printing process to ensure print quality and accuracy.

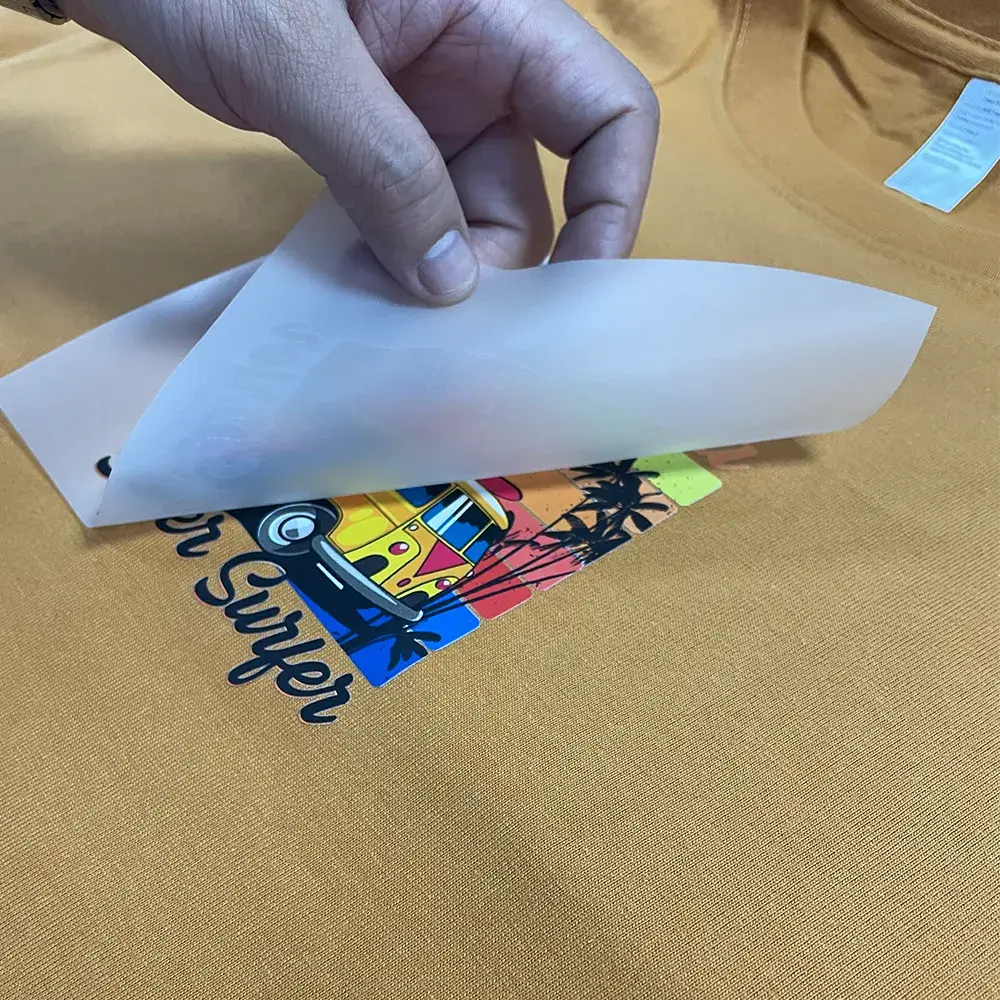

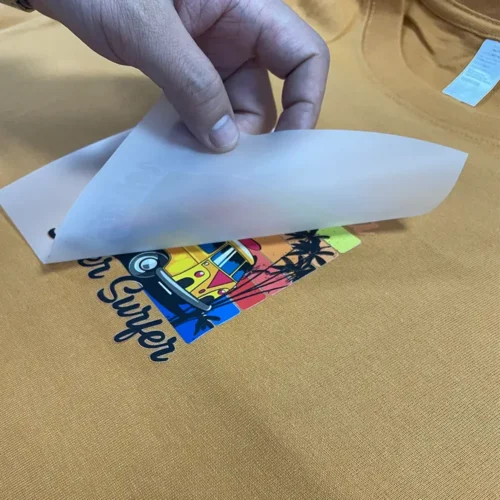

Subsequent Processing:

- After printing is completed, remove the DTF Film from the printer.

- Follow-up processing, such as heat transfer, heat press, etc., is performed to ensure the image is firmly attached to the target object.

Quality Inspection:

- Perform quality checks on printed products to ensure image quality and color accuracy.

- Make corrections or reprint if necessary.

Storage and Care:

- Store unused DTF Film in a dry, cool place away from moisture or sunlight.

- Clean and maintain your DTF printer regularly to ensure it is working properly.

The above is the general method of using DTF Film.

The steps may vary depending on the printer model and DTF Film type. It is recommended that the relevant instructions and safety precautions be read and followed carefully before use.

评价

目前还没有评价