Product Parameters - LINKO A604 DTF Printer

The Linko A604 DTF printer package includes a complete Direct-to-Film printing setup, consisting of a DTF printer, powder shaker equipment, oven, filter, 4 Epson print heads, DTF ink, DTF film, DTF powder, RIP software, installation videos, and one-on-one machine training tutorials.

| Parameter | Details |

| Model | A-6044 |

| Width | A1 | 600mm | 24 inches |

| Number of Nozzles | EPSON i3200A1*4 |

| Print Speed | 4 pass: 720*1200 dpi, 16-25 m²/h 6 pass: 720*1800 dpi, 10-16 m²/h 8 pass: 720*2400 dpi, 7-12 m²/h |

| Print Color | White (CMYK) |

| Ink Capacity | 5 Colors: 1.5L*5/color |

| RIP Software | Standard PrintFactory (Maintop optional) |

| Temperature | 15-30°C |

| Humidity | 35-65% |

| Electrical Parameters | 50 Hz/60 Hz, 220V 7A, 110V 14A, rated power 1.61 kW |

| Print Interface | Gigabit network port |

| Weight | N.W: 180 kg G.W: 263 kg |

| Dimensions (Machine) | 1885 mm * 750 mm * 1654 mm |

| Dimensions (Package) | 1920 mm * 1020 mm * 720 mm |

Linko A604 Product Highlights

Function optimization and upgrade, efficient printing.

High-precision DTF Printing

Equipped with four Epson i3200 print heads, it ensures that the A604 DTF printer operates under the dual requirements of high efficiency and high quality.

White Ink Agitation Circulation

A604 circulation method upgraded and adjusted. The tube below can also circulate to ensure that all ink is stirred.

Printer Cover Visualization

The visualization design allows you to directly see the internal working status and operation of the printer. Improve the maintenance efficiency and production efficiency of the equipment.

Professional Performance - Linko A1 DTF Printer

Electronic Display Of Temperature And Humidity

Operators can see the temperature and humidity of the production environment in real-time. They can then adjust to keep production on track.

LeadShine Motor

LeadShine integrated servo motor ensures printing stability and more accurate ink dots. The paper feeding uses a stepper motor. It ensures consistent and stable paper feeding. It also improves printing accuracy.

3 THK Guide Rail

The THK guide rail is very accurate. Its high-rigidity materials and unique design allow it to withstand high loads and maintain a stable operating state.

4 EPSON i3200*4 Nozzles

It has high precision and resolution and delicate colors. It supports multi-grayscale printing and can output smoother color gradients. With 3200 nozzles, and fast printing speed, can meet the needs of large-scale printing.

Widened and Lengthened Computer Stand

Support larger size monitors, get a better experience in image processing and rip. More convenient, flexible, and easy to operate.

Way Integrated Control Panel

The 3-way integrated touch screen controls front and rear heating, countertop lighting, and suction. It has a convenient and easy interface.

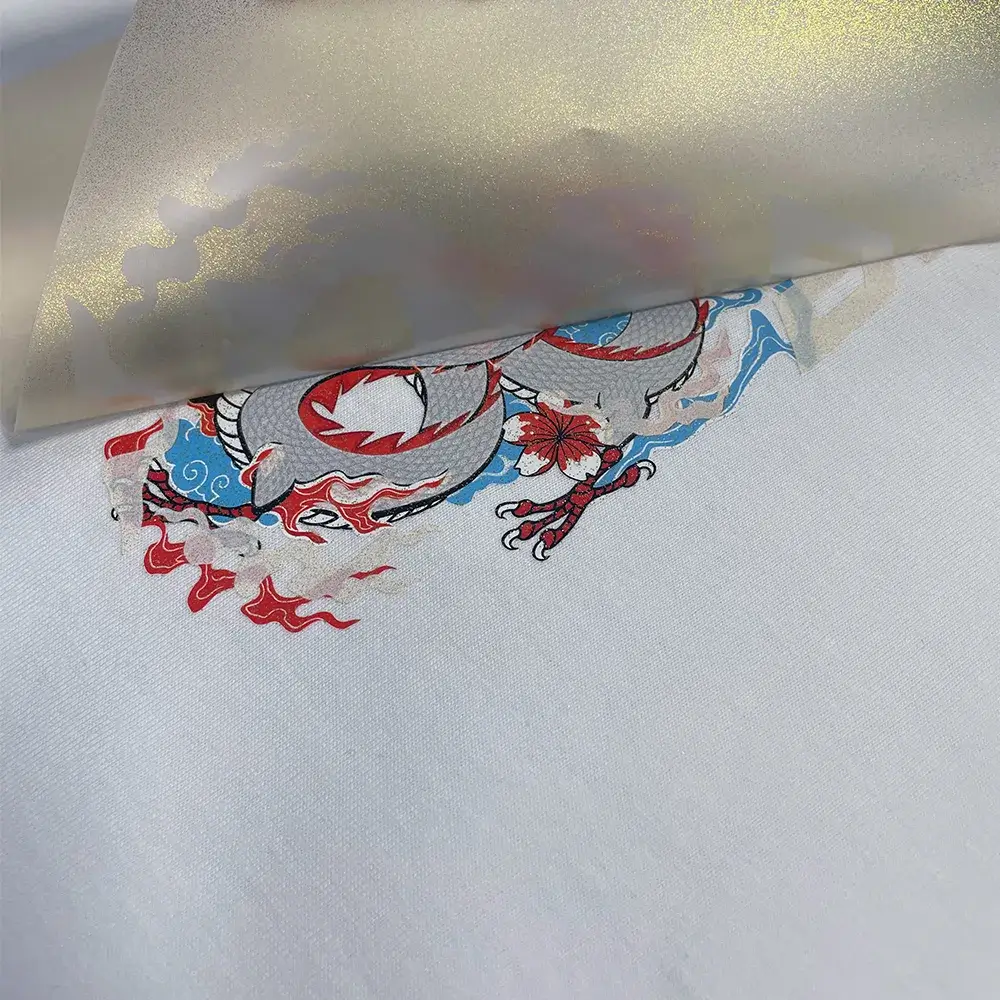

T-shirt Printing Process

① Design The Image And Lay It Out

Use RIP software to set it up. We recommend Print Factory.

② Start printing

Print the designed pattern on the DTF transfer film

③ Shake the powder

Use a powder shaker or manually to evenly apply the powder to the film with the pattern printed on it

④ Curing

Put the pattern in an oven to heat and cure

⑤ Heat press

Transfer the pattern to the clothes through a heat press

⑥ Peel

Off the film after cooling down and the printing is complete.

A1 DTF Printer Applications

LINKO DTF-A604 printer is suitable for a variety of scenarios. Its biggest highlight is that it supports fluorescent printing function, making the printed images more vivid and eye-catching. Widely used in customizing T-shirts, hats, bags and other textiles.

评价

目前还没有评价