Product Parameters - LINKO A480 A3+ DTF Printer

The Linko A480 DTF printer package includes a complete Direct-to-Film printing setup, consisting of a DTF printer, powder shaker equipment, oven, filter, 2 Epson print heads, DTF ink, DTF film, DTF powder, RIP software, installation videos, and one-on-one machine training tutorials.

| Name | High-speed A3 DTF printer & shake powder in one |

| Model | A480S |

| Brand | LINKO |

| Available width | <370mm |

| Print media | Pet film |

| Suitable for transfer media | Nylon, chemical fiber, cotton, leather, swimsuit, diving suit, PVC, EVA, etc |

| Print head | 2 Epson i3200 |

| Printing accuracy | 720*1800dpi, 720*2400dpi |

| Print speed | 6Pass: 9m/h, 8Pass: 7m/h |

| Print Assist | Front and rear arc plate heating; Platform suction: white ink circulation & stirring, all with ink shortage alarm: Anti-collision of nozzle: One key automatic cleaning;integrated auto-lifting ink station: LCD + multi-function operation keyboard |

| Platform suction | Suction adjustable |

| Powder controls | Powder shack control, Powder and amount control, etc |

| Powder shaking assist | @Front heat plate @Conveyor belt transmission Rotating touch screen to stage dryer Cold fans Smart auto-take up system |

| Print interface | Optical fiber network port |

| RIP software | Maintop |

| Operating system | Windows 7, Windows 10 |

| Temperature and humidity | 15-30°C, 35-65% |

| Electrical parameters | 220V , 20A, Rated power 4.5KW, Energy consumption: 2-4.3KW |

| Size and weight | Machine2100*1112*1209mm, N.W 320kgPackage2550*1130*1161mm, G.W 400kg |

Linko A480 Product Highlights

A3 DTF Printing & Shaking Powder, High Speed Printing

All-in-one Print Design

Combined with a top-of-the-line TPU powder shaker and dryer system. It’s ideal for businesses that value efficiency, innovation, and a clean workspace.

Dual-head High-Speed Printing

Features a dual-head Epson I3200 setup for superior print quality. 30CM suitable for A3 / A4 directly to flm printing.

One-Button Automatic Cleaning

The equipment is optimized for space-saving and easy operation, which greatly improves work efficiency.

LINKO A480 DTF Printing Machine Features

Professional Performance - Linko 24'' DTF Printer Core Technologies

Ink Out Alarm System

The ink shortage alarm system ensures continuous and stable ink supply. The lifting ink station can adjust the ink height, which is convenient for user operation and improves printing efficiency.

Adjustable Rotating Touch Screen

The touchscreen can be easily adjusted and rotated to various angles, and the high-resolution display makes it easy to navigate menus, settings, and apps.

Japan THK Silent Rail

Smooth and quiet operation. The Japanese THK silent rail greatly reduces noise interference and extends the service life of the equipment.

Touch Screen and PID Precise Temperature Control

Touch screen control and precise temperature adjustment improve efficiency. They ensure the machine’s best performance.

Hydraulic Rod

The hydraulic rod makes sure the print head can move steadily and precisely while printing. It also extends the printer’s service life.

Automatic Paper Receiving System

This system improves printing efficiency by automatically collecting and stacking printed sheets. It eliminates manual operation and reduces paper jams. It is ideal for high-volume printing.

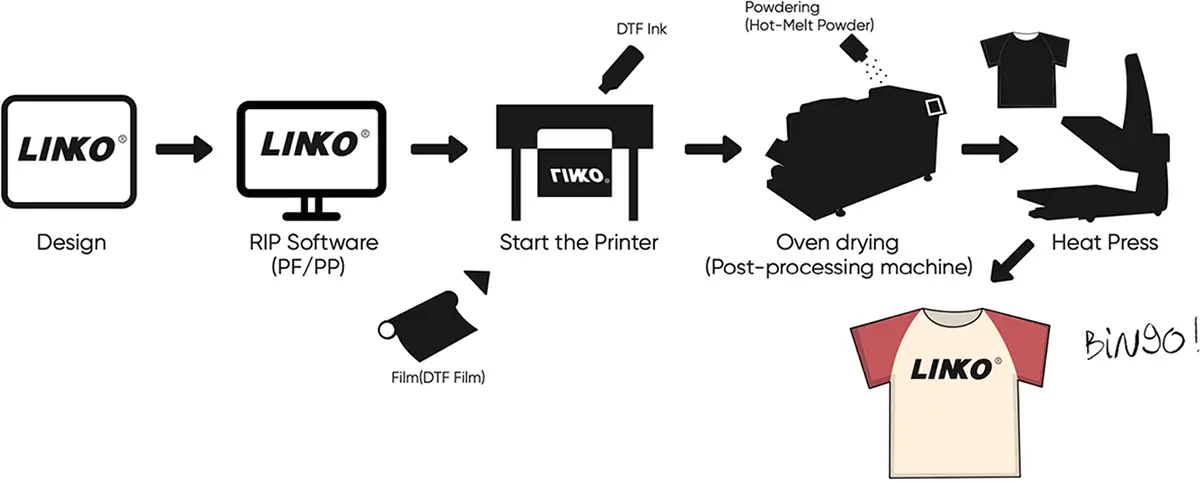

T-shirt (DTF) Printing Process

Image Preparation

Design and adjust the image file to be printed.

Print Film

Print the image on the DTF film.

Dust and Dry

Dust the image with hot melt powder and then heat and dry it.

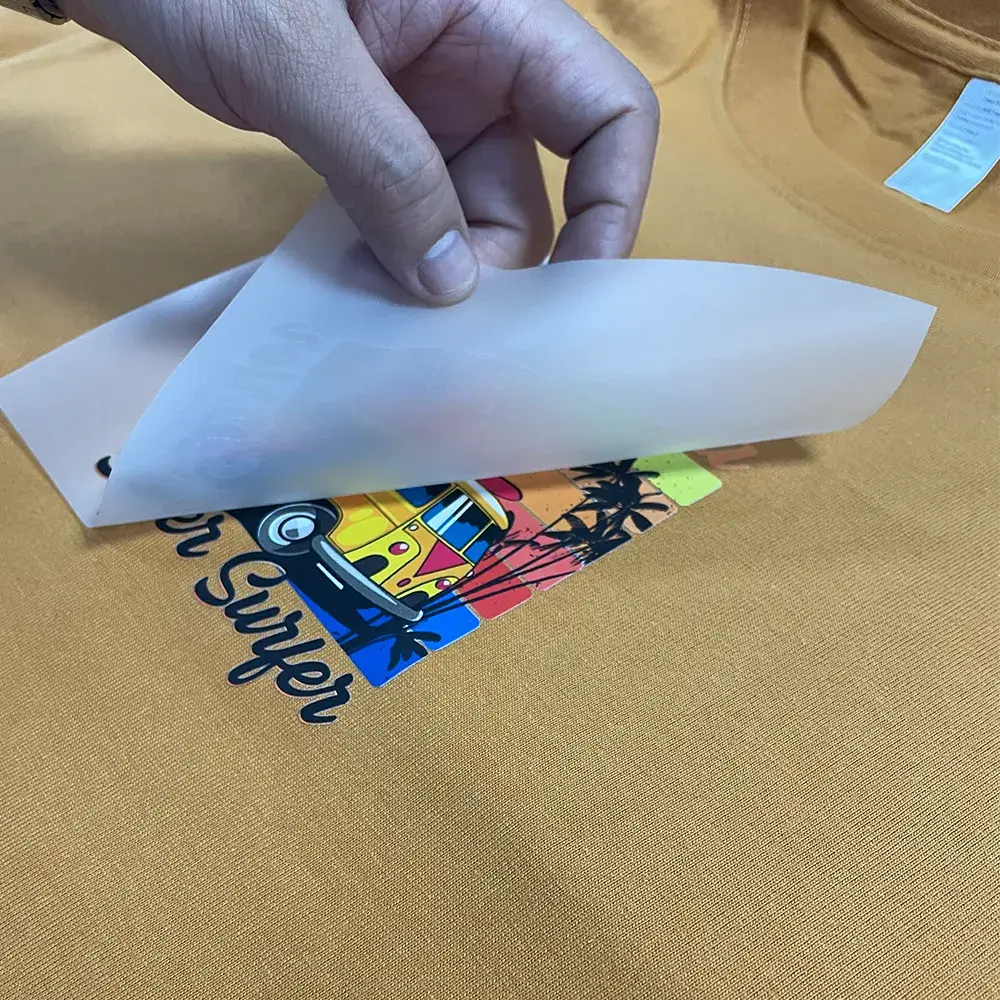

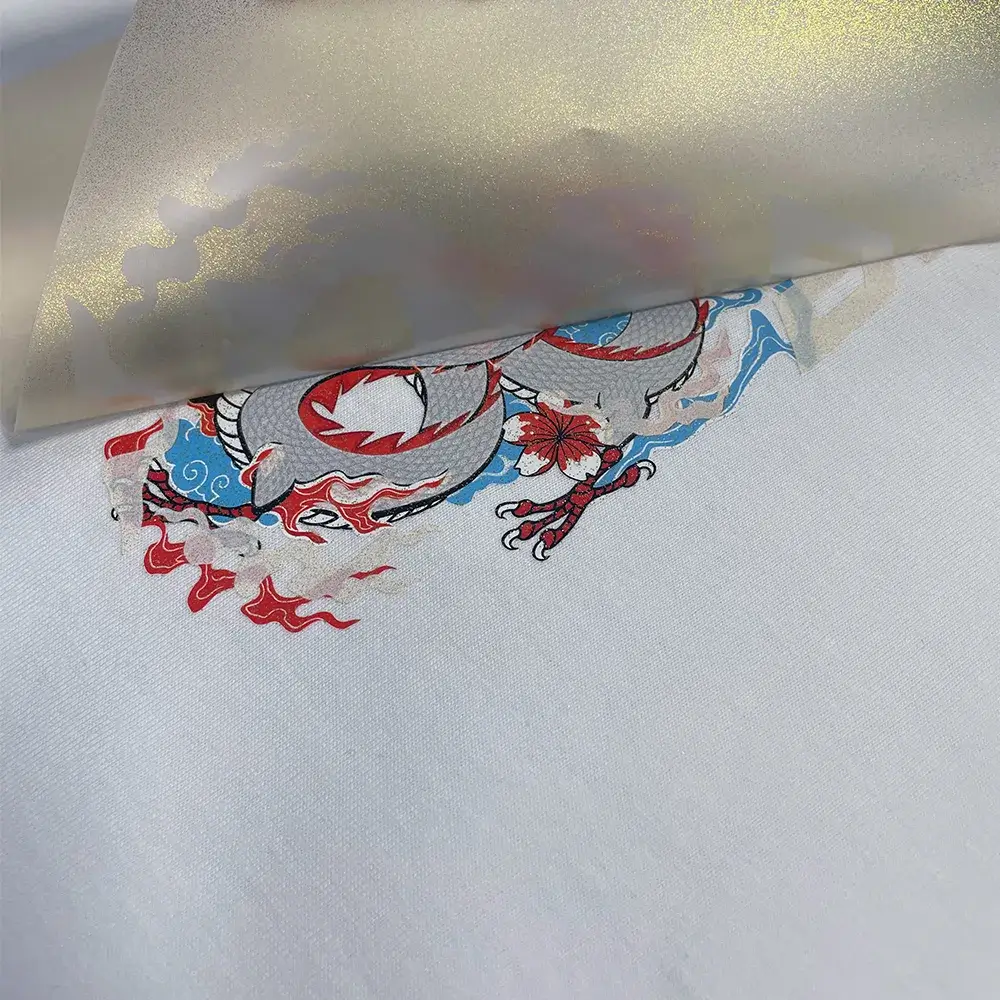

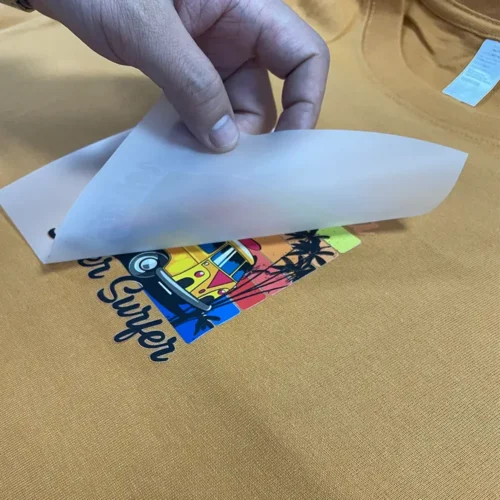

Press transfer

Put the processed film and fabric into the heat press for press transfer.

A3+ DTF Printer Applications

The A3 DTF printing and automatic dusting integrated machine is suitable for customized mass production. The application function is powerful, suitable for fluorescent color printing, and can be applied on basically all fabrics, such as T-shirts, canvas bags, sweatshirts, silk scarves, etc.

评价

目前还没有评价