Understanding DTF Printing

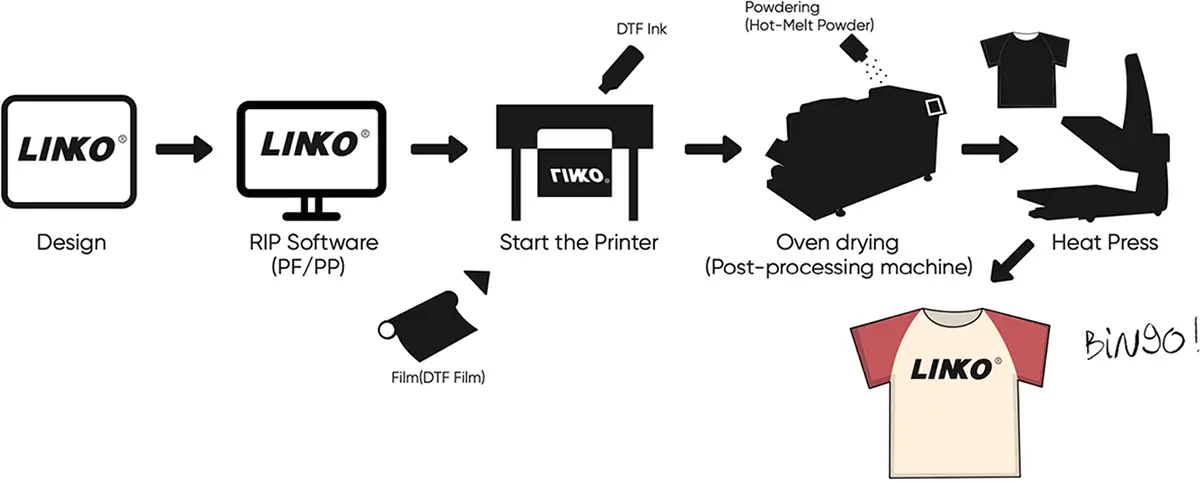

DTF printing lets you create designs on all types of fabrics (cotton, nylon, etc.) – even light or dark ones! It works by:

- Printing your design onto a special PET film.

- Shaking a hot melt powder onto the wet ink and curing it.

- Heat-pressing the design from the film to your fabric.

This method is perfect for small businesses like clothing stores, design studios, and even fast-fashion companies. Here is a guide to the best DTF printers for small business.

We offer a range of DTF printing solutions to fit your specific needs. Consider your production volume, target audience, market size, and budget. We’ll provide a custom solution with top-notch products and services, all under one roof!

Covering the following high-quality products and services:

Complete DTF Printing Solutions:

- High-efficiency A2/A3 and wide-format 24″ & 44″ printers

- Powder shaking and curing machine with extended drying tunnel and conveyor belt

- Oil fume purifier with three-layer filtration

Additional Equipment:

- Automatic hot press with balanced pressure for exceptional results

DTF Consumables:

- High-fastness inks that are:

- OEKO-TEX certified (environmentally friendly)

- White ink that flows smoothly and prevents cracking

- All colors with good elasticity and vibrancy

- DTF film with three options: hot tear, cold tear, or full-time tear (all with a 99.99% transfer rate)

- DTF hot melt powder for strong adhesion and durability

Software:

- Print Factory RIP software for:

- Perfect color matching

- Powerful calibration

- Multi-language support

- Up to 20% ink savings

Our Services & Support:

- One-stop shop for all your DTF printing needs

- Rigorous product testing for consistent print quality and traceability

- 1v1 technical support with video demonstrations

- Comprehensive after-sales training, guiding you step-by-step

We provide everything you need to get started with DTF printing!

DTF Equipment Costs

We use the A3 DTF printer as an example to analyze how small businesses can use DTF technology to make profits.

Equipment cost:

| DTF PRINTER | 2415-2750usd |

| POWDER MACHINE | 150-575usd |

| HEAT PRESS MACHNIE | 215-550usd |

| TOTAL EPUIPMENT COST | 2780-3875usd |

| DAILY MAINTAINANCE | 10-70usd |

Consumables cost (A4 size):

| Consumbales | Qty | Price 1 | Price 2 |

| 30cm*100m/roll film: 1 roll | 1 | $19.00 | $27.00 |

| white ink: 2kgs | 2 | $13.00 | $25.00 |

| CMYK color ink (total): 1kg | 1 | $16.00 | $22.00 |

| Hot melt powder: 3kgs | 2 | $6.00 | $8.00 |

| 1 roll printing cost | $73.00 | $115.00 | |

| Apportioned to each A4 cost | $0.18 | $0.29 | |

Break-even and Profit in DTF Printing

Success in DTF printing goes beyond just the equipment. To be profitable, consider factors like:

- Production volume:You’ll need to sell enough to cover costs.

- Operating costs:Factor in materials, labor, and overhead.

- Market competition:Set prices based on what customers are willing to pay.

Example: Break-even Point

Imagine a project with a $4,000 fixed cost and a $20 selling price per T-shirt (at a $12 cost per shirt). To break even (cover all costs), you’d need to sell 500 T-shirts (4,000 fixed cost / ($20 selling price – $12 cost)). Sales above 500 shirts would then generate profit.

Remember: Effective marketing, high-quality products, and good customer service are crucial for long-term success.

Invest in high-quality, stable DTF printing solutions and watch your profits soar. LINKO – Your one-stop shop for success. Contact us to successfully start your DTF printing business!