Shop or Wholesale Direct Transfer Products

Linko – Your Long Term Partner for DTF Transfer Printer

Linko DTF printer offers the ultimate printing solution for all your needs. Whether you’re looking for single-piece sampling or mass-quantity printing, our DTF printers have you covered.

Our DTF printing technology is advanced. You can use it to print custom bags, T-shirts, hats, uniforms, aprons, pillows, and more. DTF transfer printing can use different garment materials like cotton, nylon, treated leather, and polyester.

Direct to film printer are also highly customizable, meaning you can create unique designs that stand out for your products.

Plus, our DTF printing machine is easy to use, making it the perfect choice for beginners and experienced users.

Choose our direct to film transfer printers for unbeatable quality and speed.

Linko is a China DTF printer and UV DTF printer supplier. We supply one-stop solutions for DTF printers, UV DTF printers, UV printers, DTG printers, Sublimation printers, and large format inks.

We have been awarded the title of High-tech enterprise in China. Linko’s reputation extends beyond China. We have successfully cooperated with over 7,500 clients across 100+ countries and regions. We have also helped 600+ overseas people establish their businesses with DTF solutions.

You might already work in digital textile printing and want to expand your business. Or, you might be seeking industry experience and looking to start a career in textile printing. Linko can provide you with one-stop digital printing procurement services.

We offer free tech support and online training. They help streamline your operations, reduce the burden of finding and coordinating suppliers, and improve efficiency.

Why Choose Us

Company Qualification

Factory-Based Supplier

16 Years of Industry Experience

OEKO-TEK Eco Passport

Industry Leader of Inkjet Printers

Professional Team

160 Staffs

30 R&D Engineers

10 Fast-response Salesmen

27Y Average Age

Full Service

One-stop Solution

OEM& ODM Services

Free Technical Training

24-hour Online Service

Six-on-one VIP Customer Service

Customer Verification

7,500 Cooperated Clients per Alibaba Record

600+ Oversea Star-up with Our DTF Solution

100+ Agents in 65 Countries

Business Covers 120 Countries and Regions

DTF Transfer Printer FAQs

A DTF printer uses direct-to-film tech. It transfers designs onto materials like fabric, plastic, and wood.

The printer prints the design onto a special film, which is then transferred onto the material using heat and pressure.

This printing method is similar to other types of transfer printing, such as DTG (Direct to Garment).

Still, it provides more versatility and flexibility in terms of the types of materials that can be printed. See more here.

DTF printing has several advantages over other printing methods:

- It allows for printing on a wider range of materials, including those that are difficult to print using other methods.

- It is a printer that produces very sharp and highly rich-colored images, making it suitable for printing intricate designs and drawings.

- DTF printers can print big designs. They are also quite sturdy to remain intact even after several washes.

- DTF printing is cost-effective, requires less ink, and produces less waste than other printing methods.

Here is a summary of the differences between DTF printing and UV DTF printing.

DTF printers are extensively used in many areas. These include fabrics such as cotton, spandex, wool, or polyester, among others.

This makes it a versatile printing method that can be used for various applications, such as printing t-shirts, hats, bags, and other textiles.

The printed designs are colorful and cannot fade away even after several times of washing them in water.

Moreover, DFT print could be utilized on various materials of various colors, which helps in the printing process of multi-colored designs with high detail levels.

DTF printing produces better prints than other methods, like screen printing. It has bright colors, sharp details, and smooth texture.

The prints are durable, long-lasting, and withstand multiple washes without cracking or fading.

In addition, different types of materials could be printed when using DTF print, including those that proved challenging with other techniques such as plastisol or thermal vinyl transfers.

Using specialized films and inks, DFT printouts can have DTG-like photo-quality images.

DTF printers require specific types of inks that are designed to work with the specialized films used in the printing process.

These inks are usually made from pigment and resin. They have the best adhesion and durability on many materials.

Additionally, DTF inks make vibrant colors and sharp details. They can print multi-colored designs with high detail.

Therefore, choosing the right ink for your DTF printer is imperative for ensuring optimal print performance and quality at all times.

The first factor to think of when selecting a DTF printer or UV DTF printer is the function and performance it offers.

Check if it meets your print quantity and quality needs. Also, when choosing a DTF printer or UV DTF printer, consider factors like the printer’s stability and reliability. In addition, it also takes into account the brand reputation and after-sales service. In conclusion, mind about your price range. This is a buying guide for DTF printers.

Linko’s DTF printer prices range from US$1650 to US$7700, while UV DTF printers range from US$3000 to US$9900. The details depend on the model and configuration in question.

To find out the latest prices, you can ask Linko for a quote, whether you are a small business owner or want to go wholesale.

DTF consumables include DTF ink, DTF Film, hot melt powder, cleaning fluid, and moisturizing fluid.

There are three options for UV DTF consumables: ordinary AB film solution, color white AB film solution, and direct injection glue solution (partial) hot stamping.

Ordinary AB film solution and color white AB film solution consumables consist of A film with glue, white ink, colored ink, ordinary varnish, and B- films.

Hot-stamping consumables include A-film without glue inside it, glue, white colored dye, ordinary varnish (hot stamping varnish/hot stamping film), and a B-film laminating machine. More information about consumable costs can be requested by contacting us.

DTF and UV DTF printers have to be cleaned and adjusted properly at regular intervals. You must also change supplies regularly, prevent dust particles and impurities, and clear up around the workplace where they are kept. See more maintenance and care details.

Linko offers a comprehensive range of after-sales services to keep your printer in optimal condition at all times. Here is more after-sales information.

- Core accessories (mainboard, trolley board, motor, etc.) are guaranteed for 12 months.

- The device comes with a maintenance package that includes consumable accessories (ink bags, ink tubes, filters, ink pads, etc.).

- Support appointment arrangements for technicians. We will remotely debug and install equipment. Also, support door-to-door service.

- We have a 24-person professional after-sales team. Linko offers nearly 24-hour online technical service. We are ready to help you solve printing problems immediately and one-to-one at any time.

- Support free detailed operating instructions and videos.

- For agents, we can provide 3/6/12 installment passwords and one permanent password.

- We customize printing solutions. This includes your machine’s appearance and internals.

Eight: Support ICC curve debugging.

Qualification

Linko takes pride in this. Our products meet the highest standards for quality, safety, and environmental friendliness.

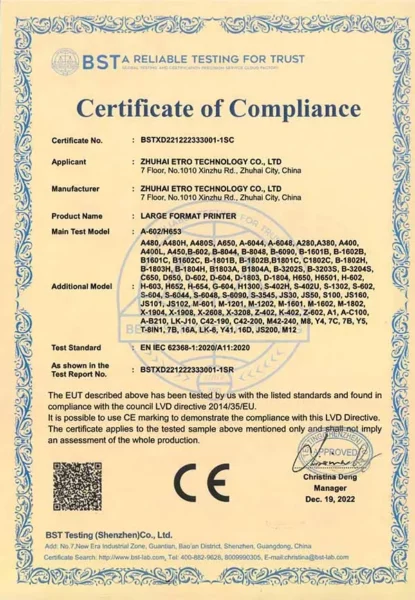

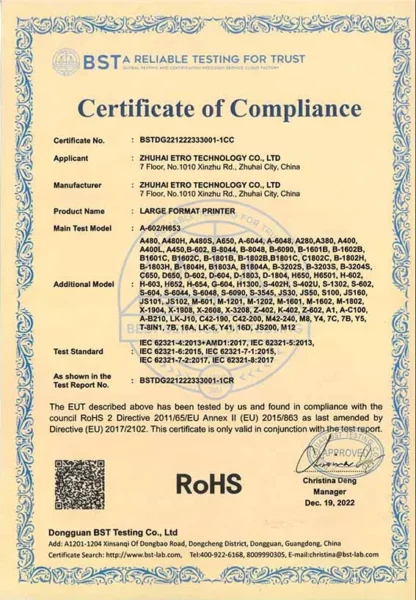

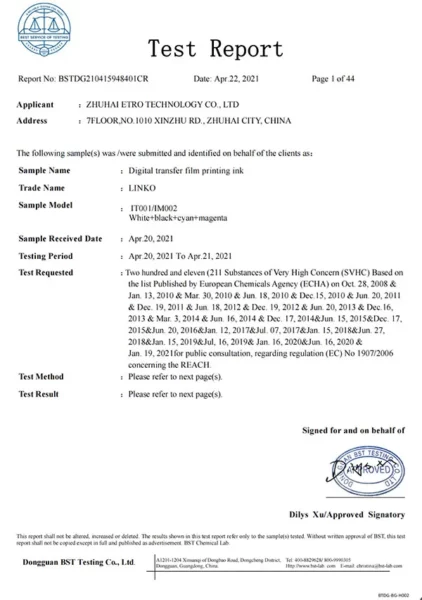

We have obtained OEKO-TEX ECO PASSPORT, CE, ROHS, and REACH certifications as evidence of this commitment.

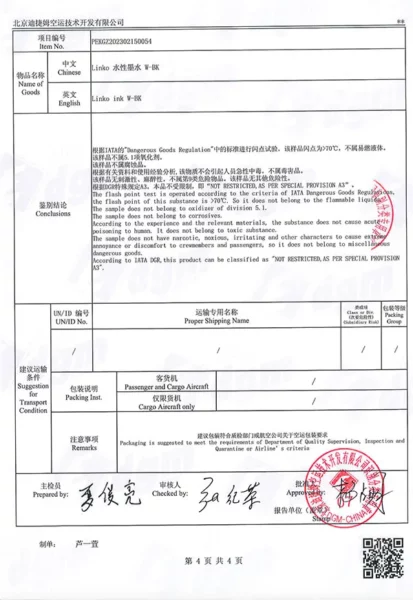

We give our customers Material Safety Data Sheets (MSDS) and dangerous goods transport reports (DGM). These make sure our products are moved and used safely.