Introduction

Direct-to-film printing consistently gains interest due to its versatility and straightforward process. Compared to other techniques, DTF printing works with various fabrics and colors.

This advantage gives this method a wider design option and better customization.

It is crucial to choose the right fabric for your project to maximize DTF printing capacity. This guide explores the various and best fabric types for DTF applications.

Best Fabrics for DTF Transfers

Here is a rundown of the best fabrics for DTF printing.

Cotton

DTF on cotton is one of the most popular. Cotton fabrics offer great binding capability with DTF inks, resulting in durable prints. Unlike other types, cotton also provides better breathability and comfort.

Polyester

Polyester is the most common synthetic fiber for DTF printing. It is often used in activewear, such as running shorts or basketball jerseys. This fabric is also the top choice for bright and crisp design transfer.

Blended fabrics

Blended fabrics are also the go-to option for many DTF printers. They combine synthetic durability and the comfort of natural fibers. Also, blended fabrics guarantee better resistance to tearing, thus protecting prints from breaking.

Nylon

The magic of DTF printing is that it works even with fully synthetic materials like nylon. Nylon fabrics often make umbrellas, backpacks, and athletic shoes. DTF works with nylon, but you should print at a lower temperature.

Spandex/ Elastane

Like nylon, spandex requires a lower heat setting in DTF printing. This fabric is famous for its use in underwear, sportswear, or other form-fitting clothes applications. However, as spandex is a stretchy fabric, durability can be compromised.

Considerations for Fabric Selection

Before running your DTF printer and heat press machine, ensure you get the most suitable fabric for the project. Here are some pointers to look for when selecting fabric.

Fabric Finish

The durability of DTF prints hinges on the fabric finish or hand feel. A smoother fabric finish has better ink adhesion than a rougher one. Synthetic fibers offer a better finish than natural fabrics but are more heat-sensitive.

Color and Texture

Color and texture significantly affect the design’s outcome. Darker garments need white ink layers for improved opacity. In contrast, lighter garments naturally offer better vibrancy and sharpness.

Better color fine-tuning is needed for darker garments to ensure the design vibrancy. White ink layers must be more pronounced to prevent toning down the details of intricate color patterns.

Fabric Thickness

Fabric thickness is an important parameter. The printing requirements differ between lightweight and heavy garments. Most synthetic fabrics are lighter than natural fibers like cotton.

How to Choose the Right Fabric for DTF Transfer

Choosing the suitable fabric for DTF transfer is not as simple as it sounds. While DTF is versatile, you still need the right fabric to maximize DTF’s unique advantages. Here are the crucial aspects to focus on.

Purpose

Knowing the proper application of the shirt you’re producing is everything. You must consider its application before picking up a cotton substrate. For instance, to make activewear, narrow your choices to synthetic fabrics. It can be polyester, blend, or spandex, but it can’t be cotton.

The same principle applies when producing hoodies or tote bags. These products are often made from natural or blended fabrics. Always know a DTF project’s specific purpose or application to land the most suitable fabric.

Budget

Budget is equally important. Always align the project budget to maximize your profit. Some fabrics have cheaper options if your client has a lower budget. For example, you can use dri-fit polyester cloths rather than spandex for activewear.

Blended fabrics can also be a cheaper alternative to whole natural fibers. Cotton blends are cheaper than pure cotton, so you can save on the material cost without compromising the overall quality.

Understanding DTF Transfers

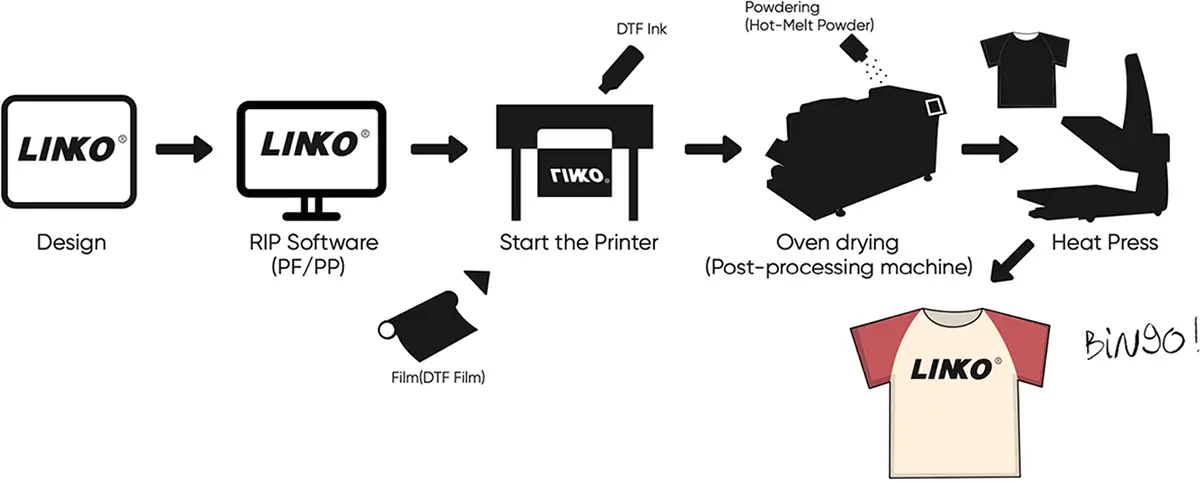

DTF printing centers around pre-printing digital images on a transfer film before heat pressing it on a substrate.

This two-phase transfer technique guarantees a durable and crisp design finish.

Unlike other methods, DTF works with white ink, allowing it to print even on jet-black garments. Its versatility is further elevated by working with most fabrics aside from cotton.

These two aspects make DTF printing a customization champion, earning a market value worth an estimated US$4.4 Billion.

FAQs

Q1: What materials can DTF transfers be used on?

DTF is limited to soft substrates like garments but works with most fabrics. It’s a method versatile enough to work with natural and synthetic fibers.

Q2: Is DTF better on cotton or polyester?

The answer depends on the outcome you are looking for. Both offer unique advantages over one another. If you’re prioritizing sharp details, you should print on polyester. You should go with cotton if you desire a comfortable and breathable fabric.

Q3: How durable is DTF transfer?

DTF transfers are known for their longevity compared to other prints. They offer better washability and resistance to peeling easily. DTF prints also maintain the vibrancy of design longer.

Q4: What are the advantages of DTF transfer compared to other transfer technologies?

DTF transfer is famous for its many advantages. Its top edge comes from its versatility and print durability.

Other methods are exclusive to one fabric color or type, while DTF works with most fibers and colors.

This method is a gem when creating a brand that offers high design customization.

Also, DTF has one of the industry’s most vibrant and sharpest print outcomes.