Introduction

Looking to invest in a DTF (Direct-to-Film) printer for your custom apparel business or creative projects?

One of the first questions that comes to mind is, how much does a DTF printer cost?

The answer depends on various factors, such as the printer’s capabilities, size, and brand.

Whether you’re a small business owner or a hobbyist, understanding the price range and what’s included in the cost breakdown can help you craft an informed decision. This guide breaks down the different types of DTF printers and the costs associated with starting this innovative printing method. Here is a detailed guide for beginners to choose DTF printers.

Understanding DTF Printing Technology

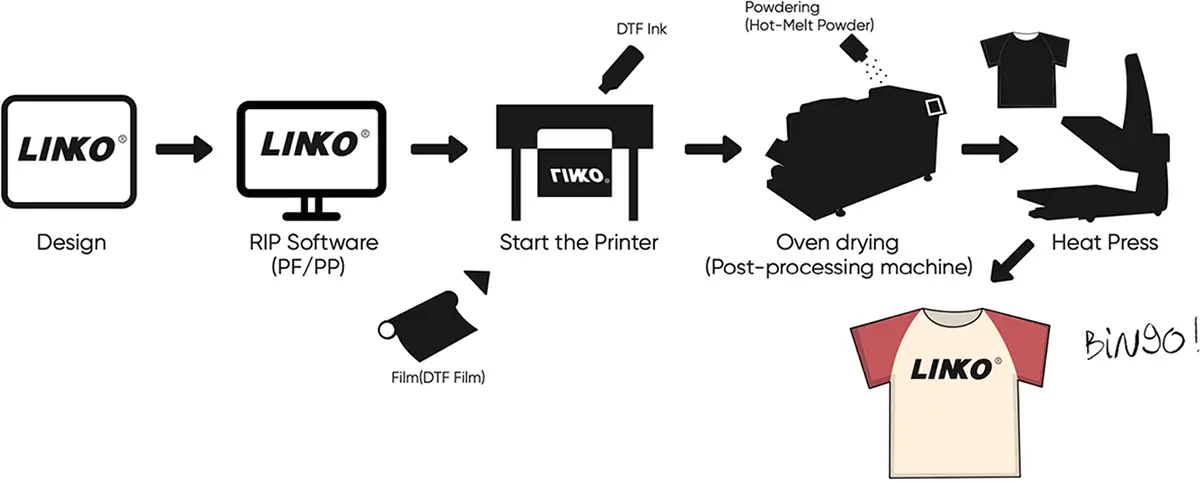

The direct-to-film printing method lies in the use of transfer film printing and thermal heat pressing. At the heart of this method are transfer films, hence its name. This technique entails printing the digital image on a PET film and curing it with an adhesive powder before running it on the heat press for design transfer.

This technique offers fast, versatile, and cost-effective printing technology.

Factors Affecting DTF Printer Costs

Plenty of factors contribute to the varying costs of DTF printers. Here are the most common to affect a printer’s price tag.

1. Printer Brand and Model

Do you ever notice how expensive well-known brands are compared to lesser-known names? It’s because when you pay for a brand, you’re not simply paying for its product alone. Premium brands have superior aftersales support, better tech integration, and higher print quality. All these aspects make the brand more reliable, hence the price tag.

2. Printer Size and Features

Larger printers that can handle bigger print areas or high-volume jobs naturally cost more. But it’s not just about size. Larger printers have advanced features like faster print speeds, higher resolutions, and more sophisticated color management. These extras not only enhance your output quality but also improve efficiency. I

3. Ink and Film Costs

When you buy a DTF printer, remember you’re not just paying for the machine. Ink and transfer film can add up quickly, especially if you print regularly. The quality and type of ink or film you use also affect your overall costs, with premium materials generally leading to higher prices.

4. Maintenance and Support

No printer lasts forever without a little TLC. Maintenance costs and the availability of customer support can also drive up the price of a DTF printer. Known brands often provide better service and quicker access to spare parts, but that convenience comes at a cost. Regular upkeep is crucial to keeping your printer running smoothly, and it’s something you’ll need to factor in.

5. Additional Equipment

To really get the most out of your DTF printer, you might need some extra equipment like curing ovens, heat presses, or powder applicators. These add-on costs can make the overall setup pricier, but they’re essential for getting high-quality results and a smoother production process.

So, while the upfront cost of a DTF printer might seem high, keep in mind that you’re investing in a reliable machine that can pay off in the long run, especially if you’re serious about growing your business or creating high-quality prints.

DTF Printer Price Ranges

Entry-Level DTF Printers

Entry-level printers are the go-to pick of many hobbyists or small-time businesses. You can own a beginner DTF printer from a minimum of US$1000 to around $3000.

Most of the time, you can save big if you opt for a converted printer. These are standard inkjet printers modified to be DTF-compatible. You do this by removing the old ink tank system from your used printer and installing a new bulk, refillable ink tank. Then, fill it with DTF inks to print it on transfer film. This hack allows you to save from the initial cost without compromising too much on the print quality.

Mid-Range DTF Printers

If you want to up a notch the print quality and capacity while staying at affordable prices, a mid-range printer is your choice. Mid-range printers are a good investment at US$3,000 to US$10,000.

You can get professional-grade prints in higher volume and speed without paying too much for industrial printers. This should be your top pick if you’re running a small-medium operation.

High-End DTF Printers

High-end DTF printers are industrial-grade equipment for faster and volume printing. Most of the time, they come with automated tech integrations and tools. They are far larger than entry or mid-range printers. Their size allows for printing for more versatile printing on larger surfaces.

To afford one, you’ll need to spend up to over US$20,000. High-end printers are suitable if you run a large commercial printing business.

How Much Does a DTF Print Cost Per Print?

Here’s a breakdown of the other operational costs in DTF printing.

1. Ink consumption

DTF inks are relatively affordable compared to other ink types. For around $80 to $120 you can have 1 liter of DTF inks. You’ll be spending around $.10 to $.30 per square inch of solid color prints in a rough estimate.

2. DTF Film cost

DTF films are another non-reusable consumable. For every print, you must shed around $.20 to $.50 per transfer film. While this expense isn’t particularly significant, you can still maximize the savings by opting for film bundles. Bundled consumables often have lower costs compared to smaller-quantity purchases.

3. Powder Adhesive

Like DTF inks, DTF powders aren’t that heavy on the pocket. From $10 to $30, you can already get your hands on one kilogram of adhesive powder. And since you only need a very thin powder coating per print, your per-print cost in adhesives is also minimal. It’s roughly $.15 per print if you are to use 1.5 grams of adhesive per shirt.

4. Pre-treatment and curing

While DTF printing generally doesn’t require pre-treatment, some machines might still need slight pre-conditioning. The cost for pre-treatment is often minimal but can range from $0.05 to $0.20 per print if specific chemicals are required.

The curing procedure can differ based on the equipment, but the cost of energy and time to cure each print can be between $0.05 to $0.15 per print.

5. Total DTF cost per print

There are many factors that add up to the overall costs of DTF printing. Besides the consumables, you’re also spending on the shirt, energy, and maintenance. The size of printable area, number colors, and design also play their part in adding to the cost.

You can expect as low as $2 per print for simple designs. If you’re printing larger designs with more colors, you’re going to spend at least $5 per shirt. In the end you can sell your DTF printed shirts for around $15 to $30 dollars. This shows the favorable profit margin of DTF printing.

DTF printing cost per T-shirt

Here’s a more concise breakdown of the DTF printing cost per T-shirt:

1. Blank Shirt Cost

The cost of a blank shirt ranges from $2–$4 for basic cotton tees to $5–$10 for premium brands. Bulk buying can significantly reduce the cost per shirt.

2. DTF Printing Cost

DTF printing costs around $1.00 to $2.50 per shirt, including ink, transfer film, adhesive powder, and curing. The cost depends on the design complexity and the quality of the materials used.

3. Labor and Overhead

Labor costs typically range from $2–$5 per shirt for printing, preparation, and packaging. Overhead (like utilities and equipment maintenance) adds about $0.50–$1.00 per shirt.

4. Total DTF Printing Cost Per T-shirt

The total cost per T-shirt ranges from $5.50 to $18.50, depending on shirt quality, design complexity, and volume. Bulk orders and simpler designs can reduce costs significantly.

Is a DTF Printer Worth the Investment?

The simple answer is YES. DTF printing is one of the most profitable methods you can venture into. Besides the lower maintenance costs, DTF consumables are also more accessible and affordable. On top of that, DTF printing offers a higher profit margin per print.

Here are the other qualities that make DTF printing a solid investment.

1. Versatility

Are you looking for a method to print on white and dark-colored garments? DTF is among the very few techniques that allow such printing flexibility. You can also print from almost all types of fabric material.

2. Quality and durability

In terms of print quality, DTF offers a vibrant and sharp finish. Following the proper printing process, you can have a DTF print that is long-lasting and fade-proof.

3. Cost-effectiveness

DTF is one of the most cost-effective printing setups. While you may have to pay a higher initial cost, running the business guarantees a faster return on investment and high profitability.

4. Profit potential

DTF printing is perhaps the most profitable printing technique in the market today, with a profit margin of around 70% to 80%.

FAQs

What type of printer do I need for DTF?

You can buy a specialist DTF printer or go for a converted one. But if you want to save, converting an old inkjet printer to be DTF-compatible is also a smart move. Whether you are a novice or a professional, the DTF printers on sale by LINKO can meet your needs.

Is DTF cheaper than screen printing?

This depends on the aspect being compared upon. If you’re talking about initial cost, DTF is the cheaper pick. DTF also wins if you are after complex designs and smaller print batch. But as the volume goes up, screen printing stands as the more cost-effective method.

How long can a DTF print last?

DTF prints are long enough to last around 100 wash cycles or several years. They may not be the most durable, but they aren’t easily worn.