Introduction

UV DTF printing is relatively new in the industry. This popular method gained fame around 2020, incorporating UV technology while rooted in the traditional DTF process.

DTF printing is already a popular and great technique for garment printing, but it cannot print on a rigid substrate. UV DTF has been introduced to address this void. You can transfer designs on wood, metals, plastics, and other hard surfaces.

Learn here why a UV DTF printer should be your next big investment.

What is UV DTF Printing?

You may already know that as versatile as traditional DTF is, it cannot print on rigid substrates. This issue is where UV DTF comes to resolve.

UV DTF uses UV DTF printers and UV-curable inks to create designs that stick to hard surfaces. This method, rooted in transfer sheet printing, produces crisp, durable, and fade-resistant designs.

However, unlike UV printing, UV DTF does not produce direct prints on hard substrates. Rather, it prints on a transfer sheet that, once printed, functions as stickers. Compared to DTF, UV DTF does not involve a heat press machine but needs a laminating machine.

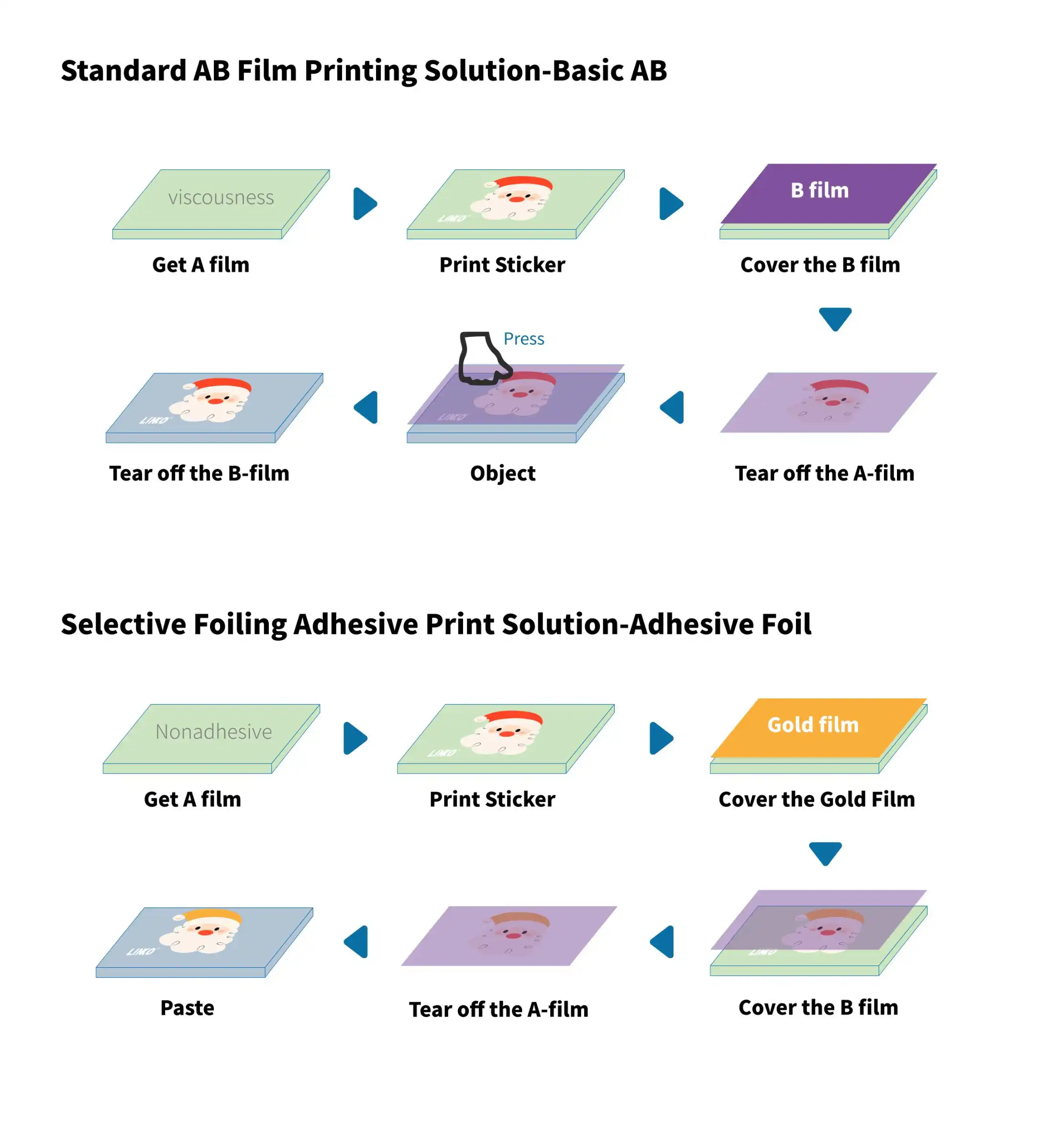

UV DTF has A and B films that you have to laminate together. The A film is for design printing, while the adhesive B film is for transfer. To transfer the design, you must press the B film onto the surface either by hand or a squeegee. Afterward, simply peel off the adhesive film.

Advantages of UV DTF Printing

UV DTF is a game-changer in the printing industry. It fills a void other methods can’t fill. Integrating UV DTF into your business makes you one step more versatile than others. Here are the advantages of UV DTF printing.

- Exceptional Print Quality

While UV DTF is relatively new, UV printers have been popular for decades. This case ensures innovation and development in design and print quality.

The UV printer’s wide colour gamut guarantees vibrant and sharp images no matter the details. UV DTF stickers have crisp designs that are obvious to the eyes and touch.

- Versatility

UV DTF has wide applications on rigid substrates. Its exceptional adhesion allows design transfer on wood, plastic, ceramics, or metal. You can even transfer the design to curved surfaces like mugs and bottles.

- Durable and Long-lasting Prints

UV-curable inks are better absorbed and bonded to the substrate. Compared to other inks, UV inks have a more robust molecular structure when cured. This process doubles its strength when transferred, making it wash-resistant and long-lasting.

- Cost-effective Solution

Applicability to small and large-scale projects ensures cost-effectiveness. UV DTF is a practical choice for small and large orders due to its fast turn-around time. Its straightforward process also lessens operational costs.

What materials can be transferred on?

The versatility of UV DTF comes from its wide material application. Its designs can stick to different surfaces without compromising its durability. Here are the materials you can use to transfer your UV DTF designs.

- Ceramics

- Smooth plastic

- PVC

- Metal

- Paper

- Glass

- Wood

- Leather

How Does a UV DTF Printer Work?

Everyone is curious about how one printing method works; the good news is that UV DTF is straightforward. Here is the step-by-step process of a UV DTF printer at work.

1. Design crafting

Like other methods, you must also craft your digital design via design software. Applicable file formats are EPS, AI, and SVG for vector formats and TIFF, PNG, and JPEG for raster formats.

It’s best to convert your colour mode into CMYK configuration for optimal results. You should also maintain a high resolution of at least 300 DPI to ensure crisp prints. Before transfer, you must also leave a bleed area or spaces around the design for cutting or trimming.

2. Film printing

Unlike traditional DTF, UV DTF includes two films. The A film is where you print your design. Position the A film on the printer’s flatbed and let it do the work in seconds or minutes, depending on the design.

Some A films are white in their original state, while others are transparent sheets. The UV printer prints the color layers on a white under base before applying the overcoat.

3. Film lamination

As mentioned, UV DTF has two films, A and B. Once you have printed the design on the A film, you must laminate it with the B film. The latter is an adhesive sheet to which the printed design will stick. If other methods require a heat press machine, you’ll need a lamination machine.

4. Design transfer

The design transfer for UV DTF is manual and economical. This step does not need any proprietary machine but your hands and a squeegee; you can even press the design with your fingers.

After separating the A film from the B film, which now contains the design, press the sticker to the surface. Apply pressure using a squeegee to ensure the film completely adheres to the surface. You must paste the B film completely flat without any air bubbles.

When you’re confident that you’ve properly pasted the B film, it’s time to peel it off. The design will now have to stick to a surface that is resistant to fading and washing.

DTF Printing vs. UV DTF Printing

You’re curious how UV DTF differentiates from DTF printing or if there’s any difference. While UV DTF borrows its process from traditional DTF printing, they remain distinct in several aspects.

The first difference between these popular methods is their application. Traditional DTF is a garment-printing method limited to soft substrates like fabric. In contrast, UV DTF intends to print on rigid substrates.

Also different is their printing process. UV DTF prints via UV printer, which requires a different process. UV DTF also involves two different transfer sheets than DTF’s one PET film. DTF needs an adhesive powder, while UV DTF’s two films must be laminated. In design applications, you only have to press print by hand for UV DTF, while DTF needs a heat press.

Nonetheless, both these techniques are respectable methods of their own. Ultimately, it boils down to their application to decide which way to go.

Why should you Choose UV DTF Printing?

UV DTF is a versatile and cost-effective technique, without a doubt. But your choice of this method should hinge primarily on your application.

If you are entering or expanding your business into rigid substrate printing, here are the top 5 best UV DTF printers for startups.

While other techniques exist for such applications, you can never go wrong with UV DTF.

This method guarantees fast turnaround time while ensuring vibrant prints every time. UV DTF is a customization champion that guarantees freedom and creativity for every design transfer.