Introduction

The textile printing industry has much to offer about available printing methods. The direct-to-film and white toner are two of the most common techniques you can employ.

These two methods are champions in producing photorealistic and durable prints. Unlike other methods, they can print on black or colored substrates. Such versatility guarantees countless possibilities for print customization.

But DTF and White Toner printing aren’t all alike. When compared, they have advantages and drawbacks. Here’s a comparison guide to help you decide which is best.

Definition of DTF Printing and White Toner Printing

Numerous methods exist in the lucrative printing industry today. Some methods are almost identical, while others can be interoperable.

This only shows that proper study is required before entering the printing business.

It’s critical to familiarize yourself with the different methods to choose the most suitable one.

Below are descriptions and meanings of two popular methods in DTF and white toner printing.

What is DTF Printing?

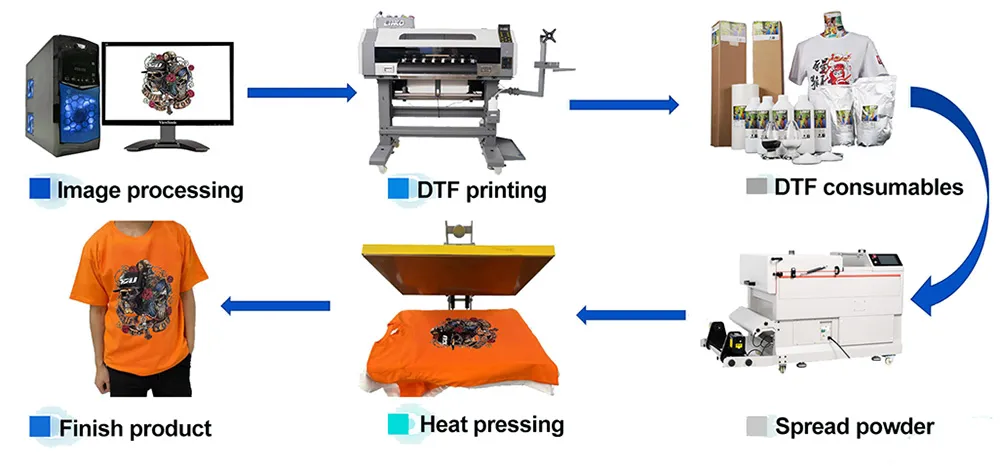

DTF printing is relatively new that’s gaining rapid popularity in the industry. This technique involves a two-stage transfer process.

First, you print your digital design on a PET transfer film.

Next, you heat press the printed film to transfer the design onto the garment.

DTF should be your option if you’re looking for a versatile and cost-effective method.

Compared to others, DTF printing works wonders for versatile applications. What is the difference between DTF printing and thermal sublimation printing?

It can print on a wide substrate option. DTF printing can be applied to almost all fabrics, such as cotton, polyester blended fabrics, etc. It is also very good at printing complex patterns on jet-black fabrics. DTF printing utilizes white ink as a base, so you can print on any fabric color.

What is White Toner Printing?

This printing method centers on applying white toner, replacing transparent toner layers.

Like DTF printing, white toner printing also prints on special transfer paper. However, there are two types of transfer sheets for specific purposes.

The first one is a one-step paper used for light-colored fabrics, and the other, a two-step paper, is suitable for black or dark-colored garments.

To use this method, you’ll need a color laser printer that works with white toner and the standard CMYK colors. Like DTF, this method works with most fabric types and colors. You can print the most intricate designs and always get accurate results.

Similarities Between DTF Printing and White Toner Printing

DTF and white toner printing are similar in several ways.

Process-wise, they both use transfer sheets and a heat press for design transfer.

While they differ in printer type, they use white as a base for CMYK colors. This results in crisp, vibrant designs that can print in most colors.

Both methods also involve adhesive after-print application.

You must spread and cure the printed film with an adhesive powder in DTF.

You must “marry” the A and B sheets in white toner printing.

Additionally, both methods support cold peel applications.

Differences Between DTF Printing and White Toner Printing

While DTF and white toner printing can be identical in several aspects, they remain distinct in other areas.

Some choose DTF over white toner due to a more significant edge in one aspect or vice versa.

Below are aspects where these methods differentiate from one another.

Printing Process

Both technical processes for DTF and white toner are very straightforward. But, some steps separate them from one another.

You need RIP software to create your design and feed it to the printer for both techniques. You also have to print the design first on a transfer sheet.

The third step is different. You’ll need a hot-melt adhesive powder for DTF to apply the adhesive.

But in white toner, you’ll have two sheets that must be pressed together. White toner includes A and B sheets you must “marry” to help the design stick to the substrate.

Still, the process for curing the adhesive remains similar for the two methods.

In DTF, the adhesive powder can be cured via a heat press, which is also used to marry the A+B sheets for white toner.

Application

Both techniques are versatile printing styles since they work on most types and colors of fabrics.

But, DTF remains more garment-focused. DTF printing is more exclusively used to print shirts, totes, or hoodies.

On the other hand, white toner has more applications. It can be used to print labels for hard surfaces like signage boards.

You can transfer designs via white toner on wood, metal sheets, and plastic substrates.

Hence, white toner printing is the go-to for printing businesses not solely focused on shirt printing.

Print Quality

While both exhibit vibrant design transfers, DTF edges white toner in this aspect. In terms of durability, DTF is more resistant to fading and cracking.

DTF prints can withstand the effects of constant washing and drying longer. Also, they are more rigid and firm compared to white toner prints on garments.

But, it does not take away the credit of how reliable white toner prints are on rigid substrates.

As mentioned, unlike DTF, this method is not exclusive to shirt printing.

White toner prints are respected for their quality and longevity when applied to hard surfaces.

Maintenance

Maintenance is a crucial factor to consider. You want to pursue a technique that requires less maintenance while remaining reliable.

DTF printers need less attention compared to proprietary color laser printers. Water-based inks used in DTF have smaller pigments that are less susceptible to clogging.

Meanwhile, white toner printers use bolder ink pigment. This means you’ll need constant cleaning of the printer head and ink tank to avoid clogging.

Pros and Cons of DTF Printing

Like any other techniques, DTF printing has its good and bad side. Below are the pros and cons you should be aware of.

Pros

- Works with most fabrics and colors

- It has a straightforward printing process

- Transferred designs are vibrant and durable

- Cost-efficient method

- Can print on a standard 6-tank inkjet printer

Cons

- Plasticised print texture

- Less breathable finish

- Exclusive for soft substrates like fabrics

Pros and Cons of White Toner Printing

Like DTF, white toner has advantages and disadvantages. Here are some of its positive and negative attributes.

Pros

- Applicable to soft and hard surfaces

- Vibrant and durable finish

- Fast and straightforward printing

Cons

- Strict maintenance

- Less durable print on garment

- Prints more susceptible to cracking and fading

DTF Printing and White Toner Printing: Which is Better?

Choosing between the two methods featured should hinge on practical factors. Ultimately, your consumer base and products should dictate which way to go.

DTF should be your choice if you’re in a shirt printing venture. DTF’s versatile and respectable prints are great for customization. You can guarantee great designs that are long-lasting and highly personalized.

On the contrary, go with white toner if you’re not garment printing exclusive. If you’re branching out to printed labels like stickers and souvenirs, this method is for you.

White toner printing is inferior to DTF’s shirt printing talks. However, it has a broader application that works with rigid substrates.

In the end, it’s a matter of application to help you decide whether to go DTF or white toner.

FAQs

- How does White Toner Printing work?

White toner replaces the transparent toner with white toner layers, hence its name. Like DTF, it prints on a transfer sheet before heat-pressing the design to the substrate. It uses a color laser printer that houses CMYK inks and white toner.

- Are there any limitations to DTF printing?

While DTF printing works with most garment color and fabric types, it has limitations. Unlike other methods, DTF only works with soft substrates like fabric. You can print on shirts or tote bags, but not on wood or hard surfaces.

- Which method is more cost-effective for small-scale printing?

DTF is an ideal choice for small-scale printing businesses. It is designed to print on individual sheets and can work with even a desktop inkjet printer. DTF is a more exclusive printing choice than white toner. Since it’s exclusive to garment printing, you can narrow your offers to personalized shirts that you can print in small batches.

- Can DTF and White Toner Printing be used for custom apparel?

Yes. Both are versatile choices for customized hoodies or tees. These methods work with most colors and fabrics, allowing for a broader design application. DTF is the most popular custom printing method. It accounts for a 67% share of the US$2.6 billion digital printing industry.

- Which printing method is better for complex and detailed designs?

DTF and white toner printing are suitable methods for intricate designs. Both ensure vibrant and accurate transfers since both work with white inks. This allows both methods to print on the whitest and darkest coloured garments without compromising the design quality.